High-Quality Corrugated Sheet Pressing Machine | Efficient Production Solutions

The Role of Corrugated Sheet Pressing Machines in Modern Manufacturing

In today’s manufacturing landscape, the demand for durable and lightweight materials has led to the increased use of corrugated sheets across various industries. These sheets, known for their wavy structure, provide excellent strength-to-weight ratios and are widely used in packaging, construction, and even automotive applications. Central to the production of these sheets is the corrugated sheet pressing machine, an innovative piece of equipment that streamlines the manufacturing process.

A corrugated sheet pressing machine operates by applying high pressure and temperature to layer a series of materials, usually paper or plastic, into a corrugated format. This process enhances the structural integrity of the sheets while maintaining a lightweight profile. The technology involved has evolved significantly over recent years, with advancements that allow for improved efficiency, reduced material waste, and increased productivity. Modern machines can produce sheets at a much faster rate than their predecessors, making it easier for manufacturers to meet the growing demand.

One of the most notable benefits of using a corrugated sheet pressing machine is its versatility. These machines can be adjusted to produce various thicknesses and types of corrugated sheets, allowing manufacturers to tailor their products to specific applications. From single-wall to double-wall configurations, the pressing machine accommodates different specifications, ensuring that businesses can provide solutions for packaging, insulation, and even soundproofing needs.

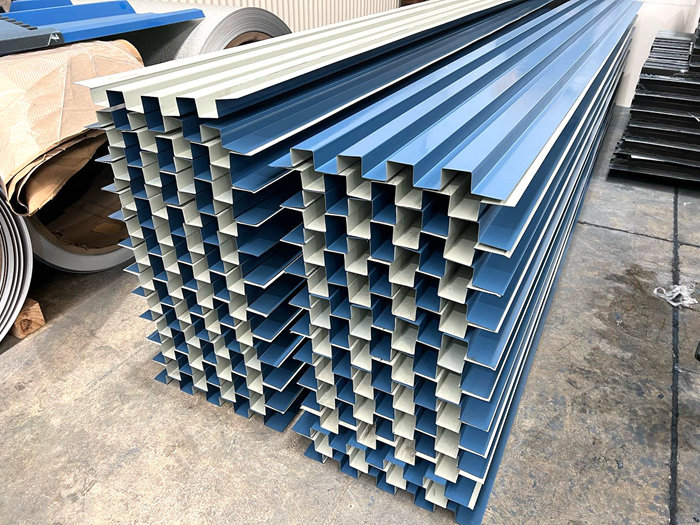

corrugated sheet pressing machine

Another advantage is the cost-effectiveness of the machines. By increasing production speed and reducing material waste, manufacturers can achieve higher profit margins. Additionally, the innovations in technology have also led to machines that are easier to operate and maintain, further lowering operational costs. Operators can quickly learn how to use the machines, which decreases the time needed for training and enhances the overall production flow.

Sustainability is also a significant factor in the design and implementation of corrugated sheet pressing machines. Many manufacturers are now focusing on eco-friendly materials and processes. The machines are capable of working with recycled materials, contributing to the circular economy and reducing the carbon footprint of production. By choosing sustainable options, businesses can not only comply with regulations but also appeal to environmentally-conscious consumers.

Furthermore, the output quality of corrugated sheets produced by modern pressing machines is significantly higher. Improved technology ensures that the sheets are uniformly pressed and cut, leading to minimal defects. This consistent quality is crucial, particularly in packaging applications where structural integrity can impact product safety and customer satisfaction.

In conclusion, the corrugated sheet pressing machine plays a pivotal role in the manufacturing sector, driving efficiency, cost-effectiveness, and sustainability. As industries continue to evolve, the demand for corrugated materials will only grow, making these machines essential tools for manufacturers aiming to stay competitive. With advancements in technology leading the way, the future of corrugated sheet production looks promising, poised to meet the needs of a diverse range of applications in an increasingly demanding market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025