c and z purlin forming machine

C and Z Purlin Forming Machine Revolutionizing Metal Fabrication

In the realm of modern construction and metal fabrication, the demand for precision-engineered profiles has surged. Among the various solutions available, the C and Z purlin forming machine stands out as a valuable tool, streamlining the production of purlins that are essential for structural framework. This article explores the functionality, advantages, and applications of C and Z purlin forming machines, highlighting their significance in the industry.

Understanding C and Z Purlins

Purlins are horizontal structural members that provide support for roofing and are typically used in steel construction. They come in various shapes, with the most common being the C and Z profiles. C purlins are characterized by their single leg and are primarily used for wall and roof support, while Z purlins have overlapping edges that enhance their strength and load-bearing capacity. The choice between C and Z purlins often depends on the specific requirements of a project, including load-bearing, spacing, and overall design.

The Functionality of C and Z Purlin Forming Machines

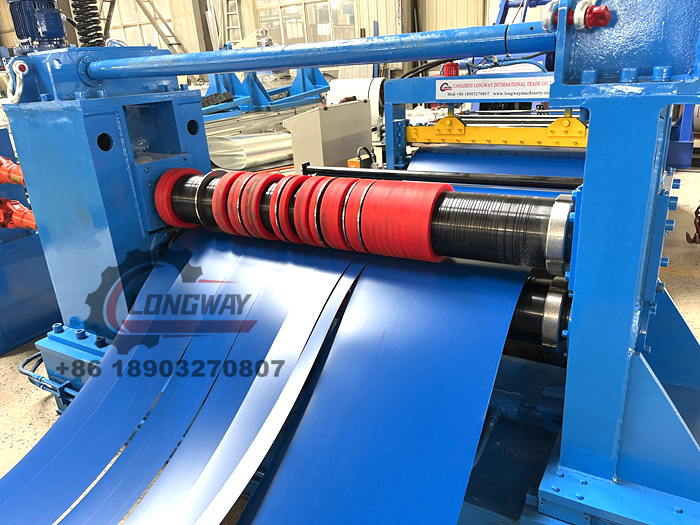

C and Z purlin forming machines are specialized equipment designed to manufacture these profiles from metal coils. The process begins with a coil of steel, which is unwound and fed into the machine. The machine then employs a series of rollers to form the metal into the desired C or Z shape. Advanced CNC (Computer Numerical Control) technology allows for precise cutting, bending, and shaping, ensuring that the finished profiles meet the stringent specifications required for construction.

Typically, these machines are capable of producing continuous lengths of purlins, which can be cut to size based on project needs. A single machine may feature adjustable settings, allowing operators to switch between C and Z profiles efficiently, thereby enhancing versatility in production.

Advantages of C and Z Purlin Forming Machines

1. High Efficiency C and Z purlin forming machines are designed for high-speed production, significantly reducing the time required to manufacture metal profiles. This efficiency translates into lower labor costs and faster project turnaround.

c and z purlin forming machine

2. Customization With modern machines equipped with CNC technology, manufacturers can easily customize the dimensions, thickness, and lengths of the purlins. This capability is crucial for meeting specific engineering requirements and project specifications.

3. Material Savings By utilizing advanced forming techniques, these machines minimize material waste. Accurate cutting and efficient production processes ensure that the maximum amount of material is converted into sellable product, enhancing profitability.

4. Durability and Strength The steel purlins produced by these machines exhibit superior strength and resistance to environmental challenges. This durability makes them ideal for various construction applications, from industrial buildings to residential projects.

5. Automation and Labor Reduction Many C and Z purlin forming machines incorporate automated features, reducing the need for manual intervention. This automation minimizes the risk of human error and allows for consistent production quality.

Applications of C and Z Purlins

C and Z purlins are widely used across various construction and engineering sectors. Their primary applications include

- Roofing Systems C purlins provide essential support for roofing sheets, ensuring structural integrity and longevity. - Building Frames Both C and Z purlins are used in the construction of frames for commercial and industrial buildings, warehouses, and hangars, showcasing their versatility. - Signage and Shelving Their load-bearing capabilities make them suitable for signage structures and shelving units in retail and storage applications.

Conclusion

C and Z purlin forming machines represent a significant innovation in the metal fabrication industry, offering efficiency, customization, and durability. As construction methods evolve, the need for reliable and precise purlin production will continue to grow. Investing in advanced forming technology not only streamlines manufacturing processes but also ensures that construction projects meet the modern standards of quality and performance. In embracing these machines, manufacturers position themselves at the forefront of metal fabrication, poised to meet the challenges of the future while delivering exceptional value to their clients. In a world where construction materials make or break a project, C and Z purlin forming machines are truly indispensable.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025