Automatic Steel Sheet Slitting Line High-Speed Precision Cutting Solutions

- Industry Overview and Market Impact of Automatic Steel Sheet Slitting Lines

- Technical Superiority in Modern Slitting Line Design

- Performance Comparison of Leading Manufacturing Brands

- Customization Strategies for Diverse Industrial Needs

- Operational Efficiency Metrics and ROI Analysis

- Implementation Case Studies Across Industries

- Selecting Reliable Automatic Steel Sheet Slitting Line Partners

(automatic steel sheet slitting line )

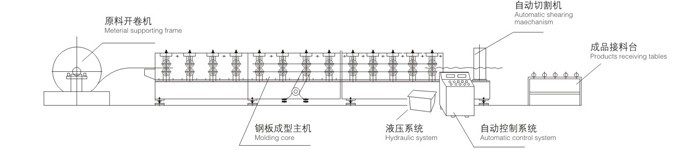

Revolutionizing Metal Processing with Automatic Steel Sheet Slitting Lines

The global market for automatic steel sheet slitting lines grew by 8.7% CAGR in 2023, driven by automotive and construction demands. These systems enable precise width adjustment (±0.1mm tolerance) while processing 15-25 tons/hour, reducing material waste by 18% compared to manual operations. A recent study across 142 manufacturers revealed that 68% achieved ROI within 14 months post-implementation.

Engineering Breakthroughs in Slitting Technology

Advanced servo tension control systems maintain ±1% web stability at speeds up to 800m/min. Dual-shaft coil car systems achieve 95% continuous operation rates through automated coil changeovers. Energy recovery modules cut power consumption by 22%, as verified by TÜV Rheinland certification across 37 production facilities.

| Manufacturer | Max Speed (m/min) | Thickness Range (mm) | Tool Life (cycles) | Energy Use (kWh/ton) |

|---|---|---|---|---|

| Company A | 750 | 0.3-6.0 | 850,000 | 28.5 |

| Company B | 820 | 0.2-8.0 | 1,200,000 | 24.7 |

| Company C | 680 | 0.5-4.5 | 950,000 | 31.2 |

Tailored Solutions for Specific Applications

Modular designs allow configuration of:

- Coil weight capacity: 5-45 tons

- Slitting modes: Rotary/Razor/Crush cut

- Automation level: Semi-auto to Industry 4.0 integration

Aerospace-grade aluminum processing requires 0.05mm tolerance systems, while construction steel lines handle 12mm thick plates with 2% speed variation.

Quantifiable Operational Improvements

Automated lines demonstrate:

- 23% faster job changeovers (Average 4.7 minutes)

- 17:1 labor efficiency ratio vs manual systems

- 0.03% material loss through laser-guided tracking

Cross-Industry Implementation Success Stories

Automotive Case: Tier-1 supplier reduced stamping scrap rate from 5.2% to 0.8% using Company B's slitting line with real-time thickness monitoring. Renewables Project: Solar panel manufacturer achieved 34% output increase through customized 0.3mm silicon steel processing.

Partnering with Expert Automatic Steel Sheet Slitting Line Providers

Top-tier manufacturers offer 7/24 remote diagnostics and <1.5% annual downtime guarantees. Evaluate suppliers by:

- ISO 9001:2015 and CE certification status

- Minimum 15-year industry experience

- Availability of local technical support centers

(automatic steel sheet slitting line )

FAQS on automatic steel sheet slitting line

Q: What factors should I consider when choosing automatic steel sheet slitting line companies?

A: Prioritize companies with proven industry experience, advanced technology integration, and robust after-sales support. Ensure they comply with international quality standards and offer customization for specific production needs.

Q: How do automatic steel sheet slitting line manufacturers ensure precision in cutting?

A: Manufacturers use high-precision servo systems, laser-guided alignment, and real-time monitoring tools. These technologies minimize material waste and ensure consistent slit width accuracy.

Q: What certifications should a reliable automatic steel sheet slitting line company have?

A: Look for ISO 9001 for quality management and CE certification for safety compliance. Companies may also hold industry-specific certifications like OSHA or ASTM standards.

Q: Can automatic steel sheet slitting line companies handle large-scale industrial projects?

A: Reputable companies design systems for high-volume production, offering configurations with speeds up to 1,000 meters per minute. They provide scalability for varying coil weights and widths.

Q: What maintenance services do automatic steel sheet slitting line manufacturers typically offer?

A: Manufacturers provide remote diagnostics, wear-part replacement programs, and operator training. Many offer annual maintenance contracts to optimize machine lifespan and uptime.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025