Affordable IBR Roof Sheet Making Machine Prices from Leading Manufacturers and Suppliers

Understanding the Pricing of IBR Roof Sheet Making Machines

The construction industry is ever-evolving, and with it comes the need for efficient and cost-effective solutions. One such solution is the IBR (Inverted Box Rib) roof sheet, which is widely used in various construction projects due to its durability, lightweight construction, and aesthetic appeal. The IBR roof sheet making machine is essential for manufacturing these sheets, and understanding its pricing is crucial for businesses looking to invest in this technology.

What is an IBR Roof Sheet Making Machine?

An IBR roof sheet making machine is designed to produce high-quality IBR sheets from coils of metal. The machine operates through a continuous roll-forming process, transforming flat metal sheets into the ribbed shapes characteristic of IBR sheets. This equipment not only enhances production efficiency but also ensures precision in dimensions and quality.

Factors Influencing Prices

1. Machine Specifications The price of an IBR roof sheet making machine can vary significantly based on its specifications. High-capacity machines that can produce sheets at a faster rate will typically cost more than simpler, lower-capacity versions. Features like automatic controls, advanced safety features, and customization options further impact the price.

2. Material Quality The quality and type of materials used in the construction of the machine also influence its price. Machines made from high-grade steel and equipped with durable components may come at a premium but can offer better longevity and performance.

3. Manufacturer Reputation The reputation of the manufacturing company can play a critical role in pricing. Established companies that have a proven track record may charge more due to their reliability and after-sales service. On the other hand, lesser-known or newer companies might offer lower prices as they work to build their reputation.

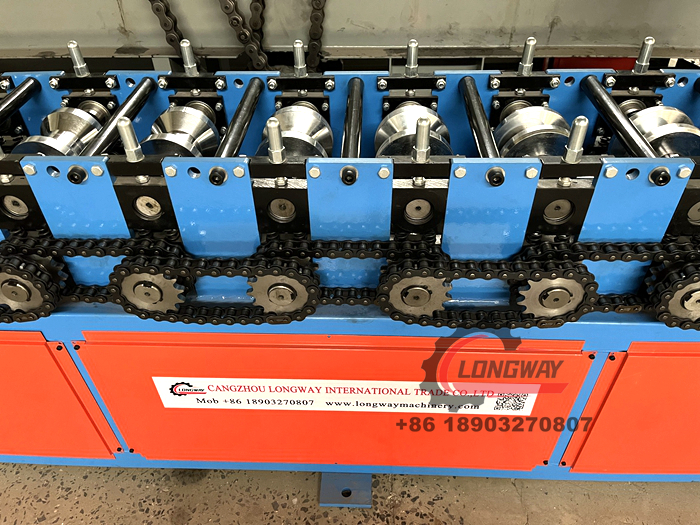

ibr roof sheet making machine price company

4. Location and Shipping Costs The geographic location of the manufacturer and the cost of shipping to your site can also affect the overall price. Local manufacturers might help reduce shipping costs, while overseas manufacturers could impose higher shipping fees that impact the total investment.

5. Additional Features Optional features like hydraulic punching, shearing systems, and integrated cutting tools can also add to the cost. Depending on the intended production scale and complexity of the roof sheets, these features can be crucial for operational efficiency.

Average Price Range

As of the latest data, the prices for IBR roof sheet making machines typically range from $10,000 to $50,000, depending on the aforementioned factors. Entry-level machines may start at the lower end of the spectrum, while high-end models with advanced technology and higher outputs can reach or exceed the upper limit.

Importance of Investment

Investing in an IBR roof sheet making machine can yield significant returns. Given the rising demand for roof sheets in construction and industrial applications, having the ability to produce them in-house can enhance profitability and reduce reliance on external suppliers. Furthermore, the quality control that comes with manufacturing your own sheets ensures that your products meet industry standards and customer expectations.

Conclusion

In conclusion, the pricing of IBR roof sheet making machines is influenced by a multitude of factors, including machine specifications, material quality, and the manufacturer's reputation. When considering an investment, it is essential to evaluate your production needs, budget constraints, and the potential for return on investment. Understanding these variables will enable you to make an informed decision and choose the right machinery for your business needs. As the construction industry continues to grow, the demand for efficient and quality manufacturing solutions like the IBR roof sheet making machine will likely remain strong.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025