Novaĵoj

-

Unveiling the Strengths of Metal Roofing Machines: Efficiency, Durability, and Environmental FriendlinessThis article delves into the myriad advantages of metal roofing machines, exploring how these cutting-edge technologies contribute to efficient production, long-lasting structures, and eco-friendly practices. Discover how the utilization of metal roofing machines enhances the efficiency and quality of construction projects while minimizing environmental impact.Legu pli

Unveiling the Strengths of Metal Roofing Machines: Efficiency, Durability, and Environmental FriendlinessThis article delves into the myriad advantages of metal roofing machines, exploring how these cutting-edge technologies contribute to efficient production, long-lasting structures, and eco-friendly practices. Discover how the utilization of metal roofing machines enhances the efficiency and quality of construction projects while minimizing environmental impact.Legu pli -

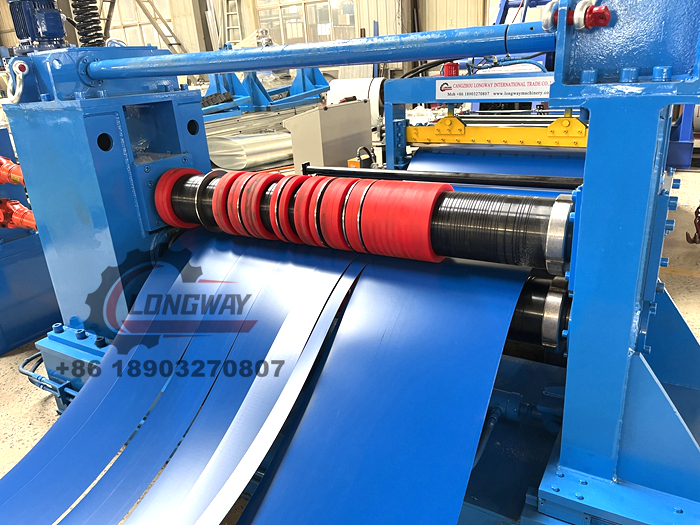

Cutting to Desired Lengths – Exploring the Versatile World of Cutting MachineryCutting machinery has revolutionized industries by providing solutions to tailor materials to specific lengths. This article delves into the machine designed for cutting materials to desired lengths, discussing its applications across various industries, including metal and wood processing. Highlighting its advantages such as efficiency, precision, and reliability, we explore how this machinery meets diverse needs.Legu pli

Cutting to Desired Lengths – Exploring the Versatile World of Cutting MachineryCutting machinery has revolutionized industries by providing solutions to tailor materials to specific lengths. This article delves into the machine designed for cutting materials to desired lengths, discussing its applications across various industries, including metal and wood processing. Highlighting its advantages such as efficiency, precision, and reliability, we explore how this machinery meets diverse needs.Legu pli -

Understanding these working principles is essential for optimizing the performance of metal roofing machinery. Manufacturers and operators need to ensure precise calibration and maintenance to achieve consistent and high-quality results in the production of metal roofing materials.Legu pli

Understanding these working principles is essential for optimizing the performance of metal roofing machinery. Manufacturers and operators need to ensure precise calibration and maintenance to achieve consistent and high-quality results in the production of metal roofing materials.Legu pli -

Mission creep is a common problem in manufacturing. The initial success of a product can trigger an unexpected level of demand, ironically leading to production volumes that are less cost-effective.Legu pli

Mission creep is a common problem in manufacturing. The initial success of a product can trigger an unexpected level of demand, ironically leading to production volumes that are less cost-effective.Legu pli -

High-strength steels have become increasingly popular for use in the automotive industry mainly because of their very high strength-to-weight ratios. However, formability in these same materials remains a problem; the yield strength is very high in these metals, which means the springback is very high. This makes roll forming parts a challenge. However, the efficiency of roll forming makes it an ideal process for producing certain parts compared to hot stamping. If you intend to roll form high-strength steels, it’s important to understand how you have to adjust your equipment to get the best results. You also have to consider the steel you are purchasing and how that is affecting the process.Legu pli

High-strength steels have become increasingly popular for use in the automotive industry mainly because of their very high strength-to-weight ratios. However, formability in these same materials remains a problem; the yield strength is very high in these metals, which means the springback is very high. This makes roll forming parts a challenge. However, the efficiency of roll forming makes it an ideal process for producing certain parts compared to hot stamping. If you intend to roll form high-strength steels, it’s important to understand how you have to adjust your equipment to get the best results. You also have to consider the steel you are purchasing and how that is affecting the process.Legu pli -

Roll forming systems used to run at a very slow speed, about 50 ft./min., Which made it easy to handle everything manually at the end of the line. These days roll formers can run anywhere from 300 to 500 ft./min. Speed can make parts hard to handle, but so can part configuration, which has become more complex as machine capabilities have expanded.Legu pli

Roll forming systems used to run at a very slow speed, about 50 ft./min., Which made it easy to handle everything manually at the end of the line. These days roll formers can run anywhere from 300 to 500 ft./min. Speed can make parts hard to handle, but so can part configuration, which has become more complex as machine capabilities have expanded.Legu pli -

Roll forming lines can be configured in two ways to create length-specific formed parts. One method is pre-cutting, which involves cutting the steel coil before it enters the roll former. The other method is post-cutting, where a profiled shear cuts the sheet after it is formed. Both methods have their advantages, and the choice depends on specific factors related to your production requirements.Legu pli

Roll forming lines can be configured in two ways to create length-specific formed parts. One method is pre-cutting, which involves cutting the steel coil before it enters the roll former. The other method is post-cutting, where a profiled shear cuts the sheet after it is formed. Both methods have their advantages, and the choice depends on specific factors related to your production requirements.Legu pli -

For decades, roll forming equipment on shop floors across the continent have formed various conventional steels with low carbon content, high ductility, yield strengths between 36 and 50 KSI, and tensile strengths up to 80 KSI. In recent years, roll formers have needed to make more parts from high-strength materials: stainless steels with tensile strengths up to 95 KSI or high-strength/low-alloy (HSLA) material with tensile strengths up to 110 KSI.Legu pli

For decades, roll forming equipment on shop floors across the continent have formed various conventional steels with low carbon content, high ductility, yield strengths between 36 and 50 KSI, and tensile strengths up to 80 KSI. In recent years, roll formers have needed to make more parts from high-strength materials: stainless steels with tensile strengths up to 95 KSI or high-strength/low-alloy (HSLA) material with tensile strengths up to 110 KSI.Legu pli -

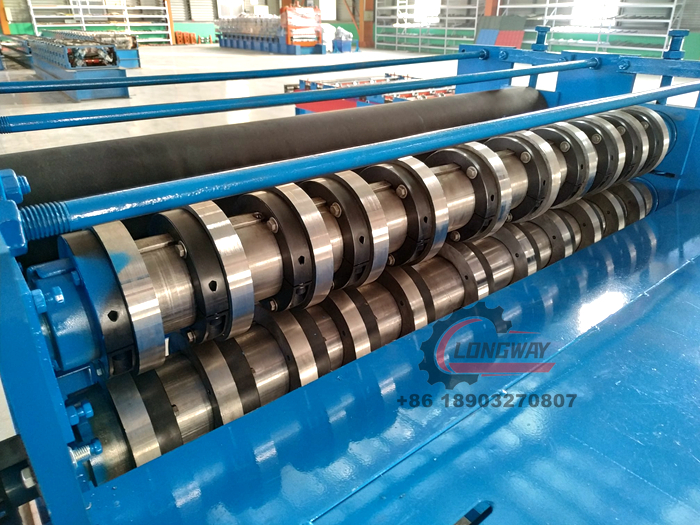

Roll forming machines are designed to form sheet metal into straight formed shapes. The process powers the flat metal through a series of continuous hardened steel rolls that shape the metal into the finished shape station by station as it passes through them. This method allows rapid prototyping of sheet metal into a variety of shapes. From simple corrugations to fully enclosed elongated shapes. The metal is gradually shaped to prevent excessive stress in specific areas. Because forming takes place by drawing, and in many cases rolling the sheet metal into coils by machine, mass production is possible.Legu pli

Roll forming machines are designed to form sheet metal into straight formed shapes. The process powers the flat metal through a series of continuous hardened steel rolls that shape the metal into the finished shape station by station as it passes through them. This method allows rapid prototyping of sheet metal into a variety of shapes. From simple corrugations to fully enclosed elongated shapes. The metal is gradually shaped to prevent excessive stress in specific areas. Because forming takes place by drawing, and in many cases rolling the sheet metal into coils by machine, mass production is possible.Legu pli -

Introduced in France in 1930 by Mr. Paul BAP, founder of Profilafroid, the steel profiles made from steel coils, also called strips in rolls, were already developed in other countries. Especially in the United States, England and Germany. nitially realized on a cold drawing bench, the process has been completely transformed by the use of machines with roller trains, called profileuse, allowing a continuous production and much faster than that of the drawing bench.Legu pli

Introduced in France in 1930 by Mr. Paul BAP, founder of Profilafroid, the steel profiles made from steel coils, also called strips in rolls, were already developed in other countries. Especially in the United States, England and Germany. nitially realized on a cold drawing bench, the process has been completely transformed by the use of machines with roller trains, called profileuse, allowing a continuous production and much faster than that of the drawing bench.Legu pli -

Sometimes it’s good to know when to ask for help. This is especially true when making decisions for a large business. At times, metal manufacturers hit a crossroads when trying to decide the best way to complete a project. Time and money are often two things at the front of a decision-maker’s mind, and a hyperfocus on these savings can lead to costly decisions.Legu pli

Sometimes it’s good to know when to ask for help. This is especially true when making decisions for a large business. At times, metal manufacturers hit a crossroads when trying to decide the best way to complete a project. Time and money are often two things at the front of a decision-maker’s mind, and a hyperfocus on these savings can lead to costly decisions.Legu pli -

All of these are crucial in the continued production of metal fabrication worldwide. Without these impressive machines and the continued improvements in technology and machinery in the metal roll forming industry, there are so many industries that would quickly become unsustainable.Metal roll forming plays a part in many everyday items that we use without perhaps even considering how they were created. They also are essential for much larger scale projects such as building construction and car manufacturing. Some items are mass-produced for businesses as well as consumers. Others are incredibly specialized and only cater to a particular market.Legu pli

All of these are crucial in the continued production of metal fabrication worldwide. Without these impressive machines and the continued improvements in technology and machinery in the metal roll forming industry, there are so many industries that would quickly become unsustainable.Metal roll forming plays a part in many everyday items that we use without perhaps even considering how they were created. They also are essential for much larger scale projects such as building construction and car manufacturing. Some items are mass-produced for businesses as well as consumers. Others are incredibly specialized and only cater to a particular market.Legu pli