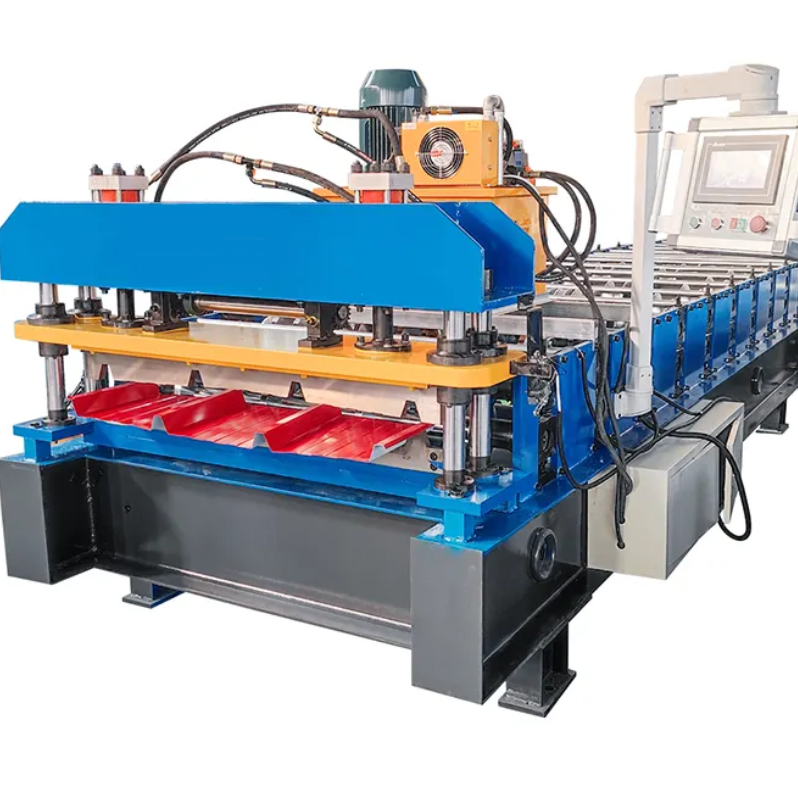

steel silo roll forming machine

Steel Silo Roll Forming Machines Revolutionizing Storage Solutions

In the ever-evolving landscape of construction and agriculture, the demand for efficient and durable storage solutions has surged. One such solution that has gained significant traction is the steel silo, a vital component for storing grains and other bulk materials. At the heart of modern silo production is the steel silo roll forming machine, a technological marvel that streamlines the manufacturing process, enhancing productivity and improving the overall quality of silos.

Understanding Steel Silos

Steel silos are cylindrical structures designed to store a variety of bulk materials, including grains, feed, and even cement. Their primary advantage lies in their durability and ability to protect contents from environmental damage, pests, and spoilage. As industries grow and agricultural practices evolve, the need for reliable and efficient storage systems has never been more pressing. The role of roll forming machines in producing these silos cannot be understated.

The Role of Roll Forming Machines

A roll forming machine utilizes a series of rollers to shape metal sheets into specific profiles. In the case of steel silos, the roll forming machine is engineered to produce consistent, high-quality steel panels that can be assembled into a silo structure. The process involves feeding flat steel coils into the machine, which then bends, cuts, and profiles the metal according to predetermined specifications.

One of the primary benefits of using a roll forming machine for steel silo production is the efficiency it brings to the manufacturing process. This automated method significantly reduces the time and labor required to create silo components, which is especially beneficial for businesses looking to fulfill orders quickly and meet growing market demands.

Key Advantages of Steel Silo Roll Forming Machines

steel silo roll forming machine

1. Customization Roll forming machines can be customized to produce various panel sizes and shapes, allowing manufacturers to create silos tailored to specific customer needs. This flexibility is crucial for meeting diverse industry requirements, whether for agricultural, commercial, or industrial uses.

2. High Precision The precision of roll forming machines ensures that each panel is manufactured to exact specifications, leading to a tighter fit during assembly and improved structural integrity of the silo. This high level of accuracy minimizes waste and reduces the likelihood of costly errors during production.

3. Durability Steel produced via roll forming tends to have enhanced strength and durability compared to other types of manufacturing methods. This results in silos that are capable of withstanding harsh weather conditions and heavy loads, ensuring the longevity of the storage solution.

4. Cost-Effectiveness By optimizing the production process and minimizing material waste, roll forming machines can lower the overall cost of producing steel silos. These savings can be passed on to customers, making high-quality storage solutions more accessible to a wider range of businesses.

5. Speed of Production The automated nature of roll forming machines allows for rapid production times. This speed is crucial in an industry where timeliness can impact overall productivity, especially during harvest season when demand for silo storage peaks.

Conclusion

The advent of steel silo roll forming machines has marked a significant turning point in the way silos are manufactured. With their ability to produce high-quality, customized panels efficiently, these machines have become indispensable tools for manufacturers in the agricultural and industrial sectors. As the need for more sophisticated and durable storage solutions continues to grow, the role of roll forming technology in producing steel silos will only become more relevant. In a world where efficiency and reliability are crucial, investing in steel silo roll forming machines is not just a trend; it’s a smart strategy for future-proofing storage capabilities. With ongoing innovations and improvements in machinery, we can expect even greater advancements in the quality and efficiency of silo production, further solidifying the significance of this technology in modern storage solutions.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025