Roof Batten Profile Rolling Machine for Efficient Construction and Durable Roofing Solutions

The Roof Batten Roll Forming Machine Revolutionizing Construction

In the evolving world of construction, efficiency and quality are paramount. One of the standout innovations that have streamlined roofing processes is the roof batten roll forming machine. This sophisticated piece of equipment not only enhances productivity but also ensures precision in manufacturing roof battens, which are crucial components in roofing structures.

Understanding Roof Battens

Roof battens are strips of wood or metal that are used to secure the roofing material to the underlying structure. They serve multiple purposes, including providing a solid base for roof tiles or sheets, allowing for proper ventilation, and enhancing the structural integrity of the roof. In modern construction, metal battens are increasingly favored for their durability, lightweight nature, and resistance to environmental factors.

The Role of Roll Forming Machines

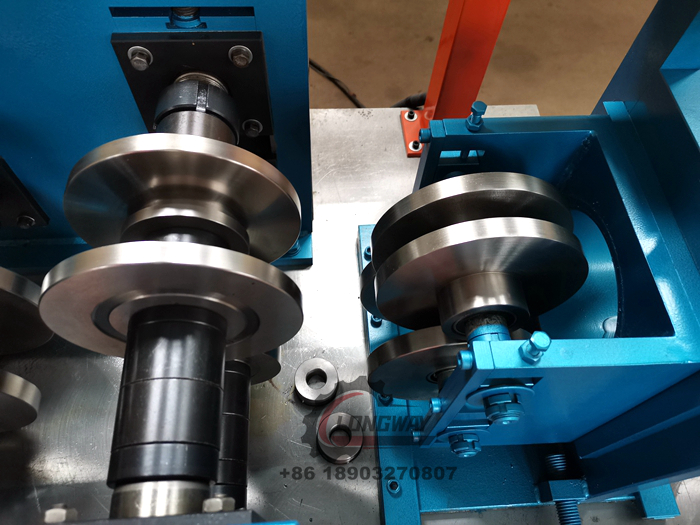

Roll forming is a continuous bending operation that forms a long strip of metal into a desired cross-section. The roof batten roll forming machine operates by feeding a metal coil into a series of rollers which gradually shape the metal into the final profile of the batten. This process allows for mass production of uniform and high-quality battens, significantly reducing labor costs and time.

Features of the Roof Batten Roll Forming Machine

1. High Precision One of the most significant advantages of using a roll forming machine is its ability to produce highly accurate profiles. The machine’s adjustable rollers and controls allow for precise customization to meet specific design requirements.

2. Automation Modern roof batten roll forming machines come with advanced automation features, including computer control systems. These systems facilitate easy adjustments and monitoring of production, minimizing human error and enhancing efficiency.

roof batten roll forming machine

3. Versatility These machines can be programmed to produce different batten profiles, catering to various project needs. This adaptability makes them an invaluable asset for manufacturers looking to stay competitive in a dynamic market.

4. Material Efficiency Roll forming minimizes waste material, as the process is highly efficient in utilizing raw materials. The machines are designed to work with a variety of metals, including aluminum and galvanized steel, enabling manufacturers to choose the best material for their specific applications.

5. Durability and Low Maintenance Roof batten roll forming machines are built to last, often featuring robust components that require minimal maintenance. This durability translates to long-term savings for manufacturers, as downtime due to repairs is significantly reduced.

Applications in the Construction Industry

The applications for roof batten roll forming machines extend far beyond traditional roofing. Industries such as residential construction, commercial buildings, and even industrial warehouses benefit from the fast production and reliable quality of roof battens. The roofing speed and strength provided by these battens contribute to quicker project completion times and enhanced performance of the roofing system.

Environmental Considerations

With the growing focus on sustainability in construction, metal roof battens offer an eco-friendly alternative to traditional wooden battens. Metal is recyclable and can be sourced from sustainable suppliers, aligning with green building practices. The efficient production process of roll forming also means less energy consumption compared to other manufacturing methods.

Conclusion

As the construction industry continues to embrace technological advancements, the roof batten roll forming machine stands out as a game-changer. By providing high-quality, precise, and versatile solutions for roof batten production, it addresses the demands for efficiency and sustainability. As we move into a future where construction practices are constantly evolving, the role of such machines will undoubtedly become increasingly vital, setting new standards for quality and performance in the roofing sector. Investing in a roof batten roll forming machine not only enhances productivity but also positions manufacturers at the forefront of innovation in the construction industry.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025