Rack and Roll Forming Equipment Manufacturer Solutions for Your Fabrication Needs

The Evolution of Rack Roll Forming Machines Transforming the Manufacturing Industry

In the manufacturing world, efficiency and precision are paramount. Among the technological innovations that have revolutionized production processes are rack roll forming machines. These machines have become essential in various industries due to their ability to create high-quality, consistent products with minimal waste. The significance of rack roll forming machines cannot be understated, as they play a critical role in producing structural components that support various applications, from shelving systems to electrical racks.

Understanding Rack Roll Forming Machines

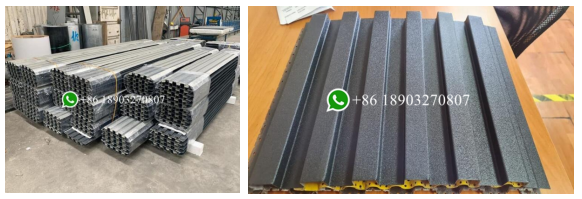

Rack roll forming machines are specialized equipment designed to produce metal racks in a continuous and automated manner. The process involves feeding metal sheets, typically steel or aluminum, through a series of rollers that gradually shape the material into the desired profile. This method of production allows for high-volume output with superior dimensional accuracy, resulting in components that meet stringent quality standards.

One of the primary advantages of using rack roll forming machines is the capacity to produce complex shapes with a single pass. The machines can be configured to produce various profiles tailored to specific industry needs, whether it's for industrial shelving, storage racks, or even customized designs for unique applications. This flexibility makes them a valuable asset for manufacturers looking to diversify their product offerings without investing in multiple machines.

The Benefits of Roll Forming Technology

1. Cost-Effectiveness Rack roll forming machines are designed for efficiency, significantly reducing production costs. The automated process minimizes manual labor and speeds up production, allowing manufacturers to scale up quickly to meet demand. Additionally, the reduced waste associated with precision roll forming means lower material costs, contributing further to savings.

2. High Quality and Consistency Roll forming technology ensures a consistent and high-quality output. The ability to maintain tight tolerances throughout the production process leads to fewer product defects and enhanced reliability. This consistency is essential in industries where structural integrity is critical.

rack roll forming machine company

3. Versatility Roll forming machines can produce a wide variety of rack profiles and designs, making them suitable for numerous applications. From agricultural storage solutions to heavy-duty industrial racks, these machines can adapt to changing market demands.

4. Sustainability In today's environmentally-conscious market, sustainability is more important than ever. Rack roll forming machines generate less scrap metal compared to traditional manufacturing methods, as the process is designed to make the most efficient use of raw materials. Furthermore, the ability to use recycled metals in production aligns with green manufacturing practices and initiatives.

Future Innovations in Rack Roll Forming

As industries continue to evolve, so do the technologies that support them. The future of rack roll forming machines looks promising, with several innovations on the horizon. Advances in automation and robotics will likely play a substantial role, as manufacturers seek to further streamline production processes. Integrating smart technologies and Artificial Intelligence (AI) can lead to enhanced monitoring, predictive maintenance, and improved product quality.

Moreover, the rise of customization in manufacturing—a trend driven by consumer preferences—will push the development of more adaptable and versatile roll forming machines. Manufacturers will increasingly require machines capable of switching between different profiles with minimal downtime, emphasizing the importance of flexibility and quick changeover capabilities.

Conclusion

In conclusion, rack roll forming machines represent a significant advancement in manufacturing technology, providing high efficiency, cost-effectiveness, and versatility. As industries continue to demand higher quality and more customizable solutions, these machines will remain pivotal in meeting those needs. With ongoing innovations and improvements, the future of rack roll forming technology is bright, promising to further transform the manufacturing landscape. Investing in such advanced machinery will undoubtedly help manufacturers stay competitive in an ever-changing market, ensuring that they can meet the demands of today while preparing for the challenges of tomorrow.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025