Durable Metal Roof Sheet Roll Forming Equipment for Efficient Production

Understanding Metal Roof Sheet Roll Forming Machines

In the construction and manufacturing industries, efficiency and precision are paramount. One of the essential tools that contribute to these goals is the metal roof sheet roll forming machine. This innovative equipment transforms metal coils into durable roof sheets, catering to a wide range of building projects. In this article, we explore the functionality, benefits, and applications of metal roof sheet roll forming machines.

What is a Metal Roof Sheet Roll Forming Machine?

At its core, a metal roof sheet roll forming machine is designed to convert flat metal sheets or coils into specific shapes and profiles that are suitable for roofing. Typically made from steel or aluminum, these machines feature a series of rollers that progressively shape the metal as it passes through. The result is a continuous sheet of metal with a consistent profile, which can then be cut to desired lengths, making it an invaluable asset for roof installation and manufacturing.

Key Components of a Roll Forming Machine

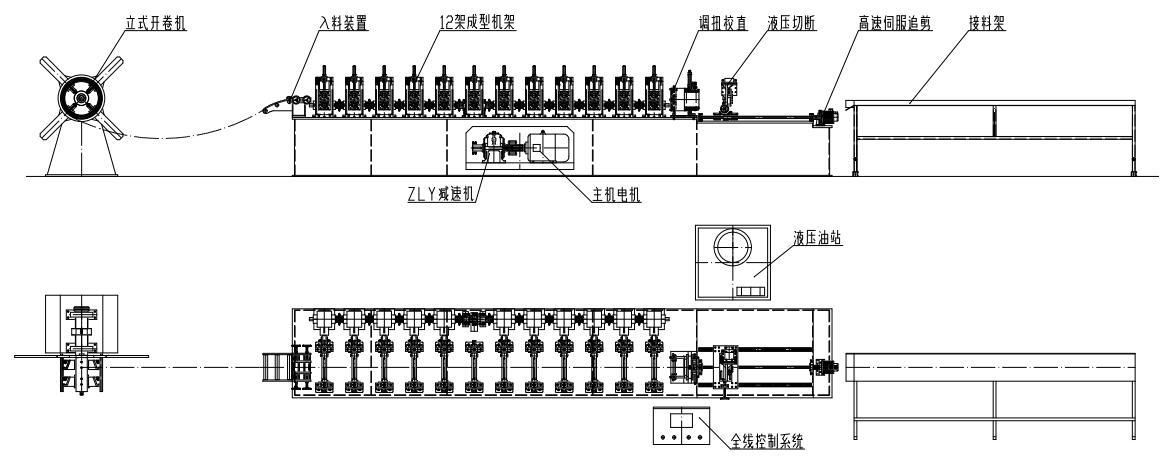

A standard metal roof sheet roll forming machine consists of several critical components. These include

1. Feeding System This component ensures that metal coils are fed into the machine smoothly and evenly. Proper feeding is crucial for maintaining uniformity in the final product.

2. Roller Stations The heart of the roll forming process, these stations are comprised of multiple rollers. Each roller is precisely designed to shape the metal incrementally, achieving the desired profile by the time the metal exits the machine.

3. Cutting System Once the metal has been formed into the correct profile, a cutting system is employed to trim the sheets to the appropriate length. This can be manual or automated, depending on the machine's sophistication.

4. Control System Modern roll forming machines often come equipped with advanced control systems that allow operators to manage various parameters, ensuring consistency in production and reducing waste.

metal roof sheet roll forming machine

Benefits of Using Metal Roof Sheet Roll Forming Machines

1. Cost-Effective Production By streamlining the roof sheet manufacturing process, these machines significantly reduce labor costs and improve material utilization.

2. High Precision and Quality Roll forming produces roof sheets with tight tolerances and uniform thickness, resulting in high-quality products that meet industry standards.

3. Versatility Metal roof sheet roll forming machines can be customized to produce a variety of profiles, including standing seam, corrugated, and other specialized designs. This versatility allows manufacturers to meet diverse customer needs.

4. Durability The metal sheets produced are robust and resilient, capable of withstanding harsh weather conditions. This durability makes them an ideal choice for both residential and commercial roofing applications.

5. Eco-Friendly Option Metal roofing is increasingly favored for its sustainability. Roof sheets made from recycled materials, combined with the longevity of metal roofs, contribute to environmentally friendly construction practices.

Applications in the Industry

Metal roof sheet roll forming machines are employed across various sectors. In residential construction, they provide roofing materials that enhance the aesthetic appeal and durability of homes. In commercial projects, these machines support the fabrication of roofing systems for warehouses, factories, and retail spaces. Additionally, they play a significant role in agricultural buildings, where sturdy and long-lasting roofs are essential.

Conclusion

The metal roof sheet roll forming machine is an indispensable tool in modern manufacturing and construction. Its ability to deliver high-quality, precise, and versatile roofing materials makes it a preferred choice for builders and manufacturers alike. As the demand for efficient construction methods grows, the role of roll forming machines will undoubtedly continue to expand, paving the way for innovations in roofing technologies.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025