high speed roll forming machine for cd ud profile factory

High-Speed Roll Forming Machine for CD and UD Profiles A Game Changer for Manufacturing

In the fast-paced world of construction and manufacturing, efficiency and precision are paramount. The advent of high-speed roll forming machines has revolutionized the production of cold-formed steel sections, particularly CD (C-Channel) and UD (U-Channel) profiles. These profiles are critical components in the construction of light gauge framing systems, commonly used in both residential and commercial building projects. This article delves into the innovative technology behind high-speed roll forming machines and their significant impact on the profile manufacturing industry.

Understanding CD and UD Profiles

CD and UD profiles are essential in the construction of drywall and ceiling systems. CD profiles, resembling the letter C, serve as tracks for the installation of drywall, providing lateral support. On the other hand, UD profiles, shaped like a U, act as the main runner for securing the CD profiles, creating a stable framework. Both profiles must meet stringent quality and precision standards to ensure structural integrity and durability.

The Role of High-Speed Roll Forming Machines

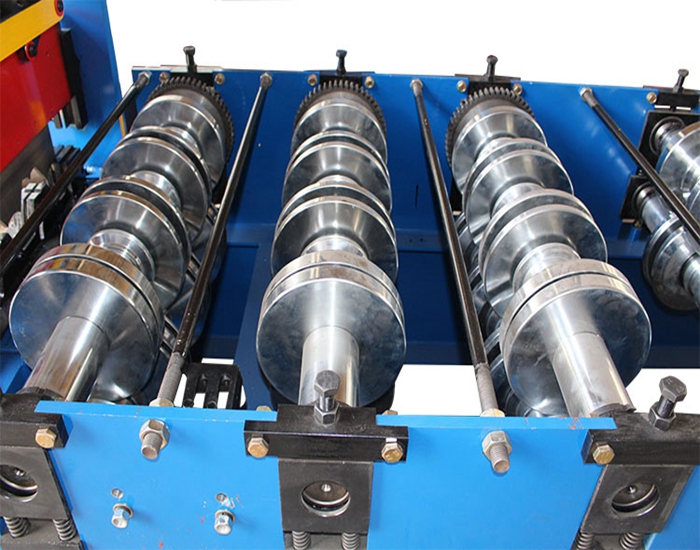

High-speed roll forming machines embody cutting-edge engineering designed to optimize the production of CD and UD profiles. These machines operate on a continuous bending process, where a series of rollers progressively shape flat metal sheets into desired cross-sectional profiles. The process is not only fast but also allows for high uniformity and accuracy, minimizing material wastage and production costs.

1. Efficiency and Speed One of the most significant advantages of high-speed roll forming machines is their efficiency. Capable of producing profiles at rates exceeding 100 meters per minute, these machines drastically reduce lead times from design to finished product. This rapid production capability enables manufacturers to meet the rising demand in a competitive market, ensuring timely project completions.

2. Precision Engineering Welding, cutting, and assembly processes can introduce errors. However, the consistency provided by high-speed roll forming minimizes variances in profile dimensions. Using computerized controls, manufacturers can adjust parameters in real-time, ensuring that every section produced meets pre-set specifications. This precision translates to better fit and finish when profiles are assembled on-site, ultimately contributing to the structural stability of buildings.

high speed roll forming machine for cd ud profile factory

3. Versatility in Design Modern roll forming machines are highly versatile, accommodating a wide range of materials—from mild steel to galvanized and stainless steel. Manufacturers can easily switch between different profile designs, allowing for customization based on specific project requirements. This flexibility is crucial in today's industry, where bespoke solutions are often demanded by clients.

4. Labor Reduction High-speed roll forming machines significantly reduce the need for a large workforce in the production process. Automation and streamlined operations mean fewer workers are needed on the shop floor, leading to lower labor costs. Additionally, the reduced risk of human error contributes to overall product quality, which is essential in construction applications.

Industry Implications

The adoption of high-speed roll forming technology has several implications for the manufacturing industry. Firstly, it encourages investment in advanced machinery, promoting technological innovation. Companies that embrace this technology can enhance their market competitiveness, offering faster turnaround times and superior quality products.

Moreover, the increased efficiency of production not only reduces costs but also positively impacts supply chain dynamics. With higher output and lower production costs, manufacturers can offer more competitive pricing, benefiting both suppliers and end-users.

Conclusion

In conclusion, high-speed roll forming machines for CD and UD profiles represent a transformative advancement in the construction and manufacturing sectors. As the industry continues to evolve, embracing such innovative technologies will be crucial for companies aiming to enhance efficiency, reduce costs, and maintain high-quality standards. The future of construction increasingly depends on these sophisticated machines, underscoring their importance in shaping a more efficient and resilient built environment. The continued development and implementation of high-speed roll forming technology will undoubtedly play a significant role in meeting the challenges of modern construction projects.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025