drywall roll forming machine material

Understanding Drywall Roll Forming Machines Material Considerations

In the construction industry, drywall is a pivotal component used for interior walls and ceilings. As demand for efficient and cost-effective construction materials has surged, the importance of modern manufacturing methods, particularly the drywall roll forming machine, has significantly increased. This article delves into the materials involved in the production processes of drywall roll forming machines and their implications on quality, efficiency, and overall construction outcomes.

Drywall, also known as gypsum board, is made primarily from gypsum (calcium sulfate dihydrate), paper, and other additives. In the roll forming process, metal components, typically cold-rolled steel, are often utilized to create the necessary framing structures for drywall systems. The choice of material is crucial, as it affects the weight, durability, and performance of the drywall assemblies.

Material Composition in Drywall Production

1. Gypsum Board The core material of drywall is gypsum, which provides fire-resistance properties, sound insulation, and thermal efficiency. It is crucial for the gypsum to be sourced from high-quality deposits to ensure a consistent and reliable product. Additionally, the paper used to cover the gypsum must be durable enough to withstand the handling and installation processes.

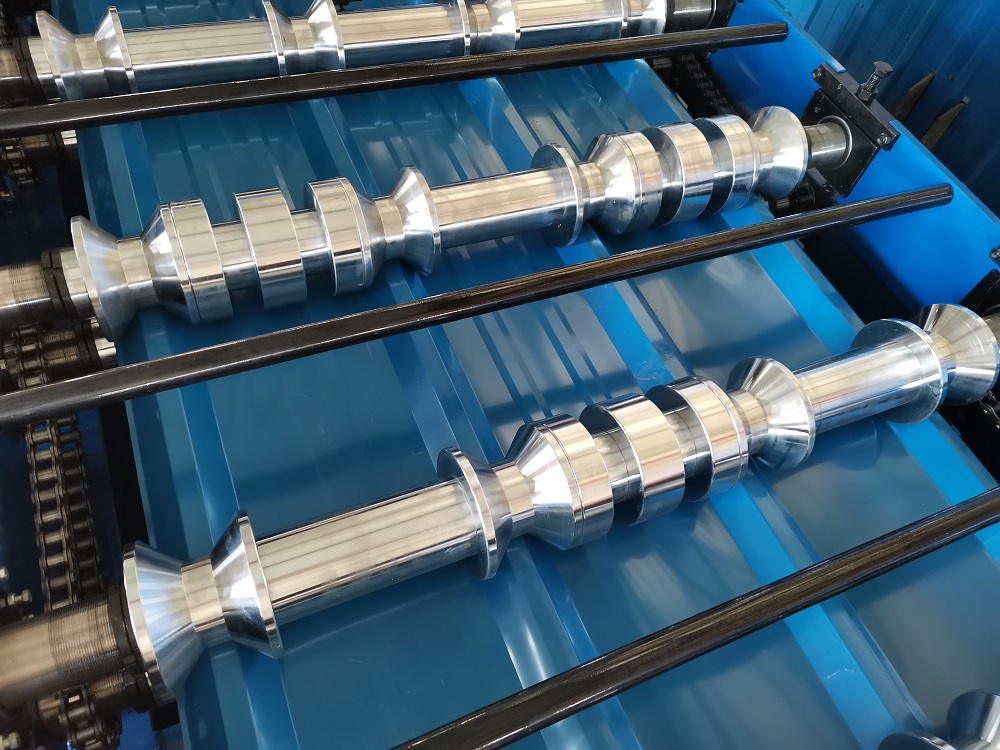

2. Steel Framework The framing for drywall applications is often fabricated using galvanized steel due to its strength and resistance to corrosion. The use of roll forming machines allows for precision bending and shaping of steel sheets into studs and tracks that provide structural integrity to the walls. The choice of steel thickness can also influence the overall stability and load-bearing capacity of the finished wall.

3. Additives and Enhancements Various additives may be integrated into the gypsum mixture to enhance fire resistance, mold resistance, and acoustic performance. These additives can include fiberglass, vermiculite, and other materials that modify the physical properties of the drywall.

drywall roll forming machine material

Efficiency Through Roll Forming Technology

The drywall roll forming machine automates the production of metal framing components, significantly increasing efficiency and reducing labor costs. One of the critical advantages of this technology is its ability to produce long lengths of framing in a continuous process, minimizing waste and maximizing material utilization.

Moreover, roll forming machines ensure precision in the dimensions of metal components, which leads to better-fitting drywall installations. This level of accuracy reduces the likelihood of errors during construction, which can result in costly rework and delays.

Quality Control and Material Integrity

The interaction between material choice and machine technology significantly affects the quality of the final product. Implementing stringent quality control measures at various stages of production is essential. This includes testing the strength and stability of both the gypsum board and the metal framing produced by the roll forming machine. By maintaining high standards, manufacturers can ensure that their products meet or exceed industry codes and resist environmental factors over time.

Conclusion

The incorporation of advanced roll forming technology in drywall production represents a significant step forward in the construction industry. Understanding the materials involved—from gypsum to steel—highlights the importance of quality and efficiency in wall system manufacturing. As the industry continues to evolve, the integration of innovative materials and technologies will undoubtedly shape the future of drywall applications, leading to safer, more sustainable, and economically viable building practices.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025