drip edge machine factory

Understanding the Drip Edge Machine Factory A Key Player in the Roofing Industry

In the roofing industry, precision and efficiency are paramount. One of the critical components that ensure longevity and functionality of roofing systems is the drip edge. The drip edge is a metal flashing that is installed at the edges of the roof, directing water away from the fascia and preventing moisture from seeping underneath the shingles. As demand for quality roofing products increases, the importance of a specialized drip edge machine factory rises significantly.

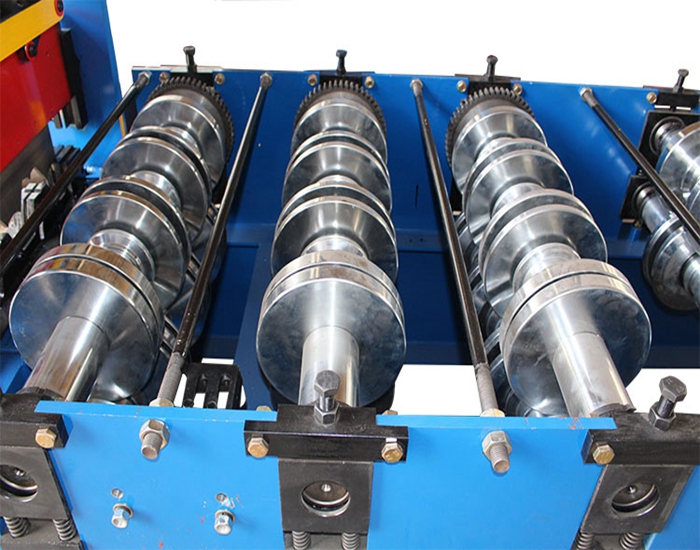

What is a Drip Edge Machine?

A drip edge machine is a specialized piece of equipment designed to manufacture drip edges efficiently and with high precision. These machines can produce various types of drip edges in different materials, including aluminum, galvanized steel, and copper. The ability to create customized profiles allows roofing contractors to meet specific project requirements, ensuring that installations are both effective and aesthetically pleasing.

The Importance of Drip Edge in Roofing

Drip edges serve multiple purposes in roofing systems. Primarily, they protect the roof structure from water damage, which can lead to rot, mold, and other expensive repairs. By channeling water away from critical areas, drip edges play a crucial role in enhancing the lifespan of roofing materials. Additionally, they provide a finished look to the roof, contributing to the overall curb appeal of a building.

As the demand for energy-efficient and sustainable roofing solutions grows, the drip edge machine factory must stay ahead of industry trends. Many manufacturers are now focusing on eco-friendly materials and production practices to meet consumer preferences and regulatory standards.

Manufacturing Process in a Drip Edge Machine Factory

The manufacturing process in a drip edge machine factory typically involves several key stages

drip edge machine factory

1. Material Selection The process begins with sourcing high-quality materials such as aluminum or galvanized steel. Quality materials are essential to ensure durability and resistance against corrosion.

2. Cutting and Forming Once the materials are prepared, the drip edge machine cuts them to the required dimensions. Advanced machinery uses computer numerical control (CNC) technology to achieve precise cuts and shapes. The forming process then shapes the metal into the desired profile, often referred to as the “drip edge,” which includes a flange to direct water and an angled edge for proper water runoff.

3. Finishing After forming, the edges undergo various finishing treatments. This may include painting, coating, or anodizing, depending on the desired aesthetics and functionality. The finishing process not only enhances appearance but also adds to the durability of the drip edge.

4. Quality Control Rigorous quality control checks are essential at every stage of production. This process ensures that the final products meet industry standards and specifications. Manufacturers often conduct tests on materials for strength, durability, and resistance to environmental factors.

5. Packaging and Distribution Once the drip edges pass quality control, they are packaged for delivery. Efficient logistics ensure that products reach customers promptly, which is critical in a fast-paced construction environment.

Innovations in Drip Edge Manufacturing

As technology advances, drip edge machine factories are embracing innovations that streamline operations and enhance product quality. Automation and robotics are increasingly utilized to improve production efficiency, reduce labor costs, and minimize human error. Additionally, the integration of smart technology allows for real-time monitoring of production processes, enabling manufacturers to optimize output and maintain high standards.

Conclusion

The drip edge machine factory plays a vital role in ensuring the functionality and longevity of roofing systems. By providing high-quality, precision-engineered drip edges, these factories support roofing contractors and contribute significantly to the overall health of buildings. As the industry evolves, staying abreast of technological advancements and market trends will be essential for continuous improvement and sustainability in drip edge manufacturing.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025