custom steel roof roll forming machine

Custom Steel Roof Roll Forming Machines Revolutionizing Roof Construction

In the ever-evolving construction industry, the demand for durable and efficient building materials is at an all-time high. Among these materials, steel has gained prominence due to its unmatched strength, longevity, and versatility. As a result, custom steel roof roll forming machines have emerged as a crucial technology in the production of steel roofing sheets, offering tailored solutions that meet specific design and performance requirements.

Understanding Roll Forming Technology

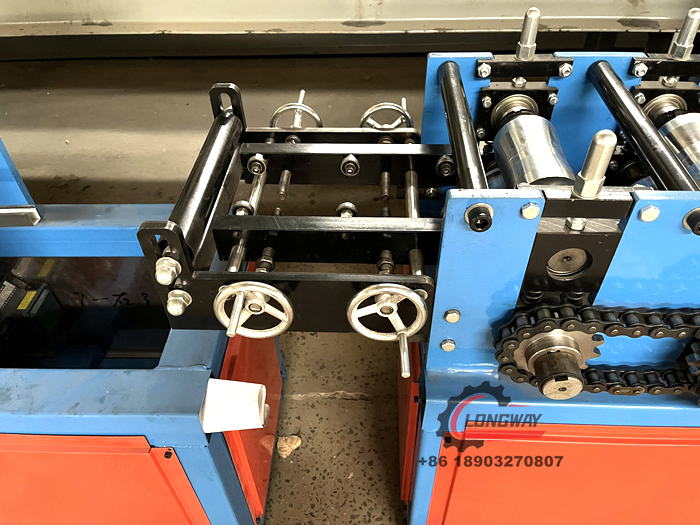

Roll forming is a continuous bending operation that progressively shapes a long strip of metal, typically steel, into a desired cross-sectional profile. The custom steel roof roll forming machine employs a series of rollers, each designed to incrementally contort the metal strip into the specific design of the roofing product—be it standing seam panels, corrugated sheets, or other intricate profiles. This highly automated process allows for high production rates with minimal waste, making it an economical choice for manufacturers.

Benefits of Customization

One of the primary advantages of using custom steel roof roll forming machines is the ability to produce roofing sheets tailored to the exact specifications of a project. Traditional roofing solutions often come with fixed dimensions and designs, limiting flexibility. However, custom machines can cater to varying thicknesses, widths, and lengths, enabling architects and builders to realize their creative visions without compromise.

Whether it’s a unique pattern for a residential project or high-performance materials for industrial applications, custom roll forming machines can accommodate unique design specifications that standard products may not meet. This capability not only enhances aesthetic appeal but also ensures that the roofing materials are optimized for performance, reducing potential issues related to weathering and structural integrity.

Efficiency and Sustainability

The efficiency of custom steel roof roll forming machines is another compelling reason for their adoption. These machines can operate at high speeds, significantly reducing manufacturing time compared to traditional production methods. Moreover, due to the precise nature of the roll forming process, there is minimal scrap material produced, making it a more sustainable option. The ability to use recycled steel as a raw material further enhances the eco-friendliness of the roofs produced.

custom steel roof roll forming machine

Furthermore, the customization aspect minimizes the need for excess inventory. Instead of investing in a wide range of pre-fabricated roofing products, manufacturers can create batches of sheets according to actual demand, thereby optimizing production efficiency and storage costs.

Applications Across Industries

The versatility of custom steel roof roll forming machines spans several industries, including residential, commercial, and industrial sectors. For residential buildings, custom roofing profiles can enhance curb appeal and support diverse architectural styles. In commercial constructions, customized solutions provide the durability needed to withstand environmental stressors while maintaining aesthetic value.

Additionally, in industries such as agriculture and manufacturing, where functional utility is paramount, these machines allow for the production of robust roofing solutions that provide excellent insulation and weather resistance. Custom designs can also facilitate specialized features such as integrated drainage systems, enhancing the overall functionality of the roofs.

Fostering Innovation

As the construction industry moves toward advanced practices, the demand for innovative roofing solutions is increasing. Custom steel roof roll forming machines are at the forefront of this transformation, empowering manufacturers and builders to explore new design possibilities. The integration of technology, such as computer-aided design (CAD) software, enables rapid prototyping and design validation, making it easier to bring creative ideas to life.

Conclusion

In conclusion, custom steel roof roll forming machines represent a significant advancement in the way roofing materials are produced and utilized. Their ability to provide bespoke solutions, coupled with enhanced efficiency and sustainability, positions them as an invaluable asset in the construction landscape. As the industry continues to evolve, these machines will undoubtedly play a pivotal role in shaping the future of roofing, offering both functionality and aesthetic value that aligns with modern building practices. Embracing this technology can lead to more durable, efficient, and visually appealing roofing solutions that meet the diverse needs of today’s builders and architects.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025