Φεβ . 16, 2025 05:47

Back to list

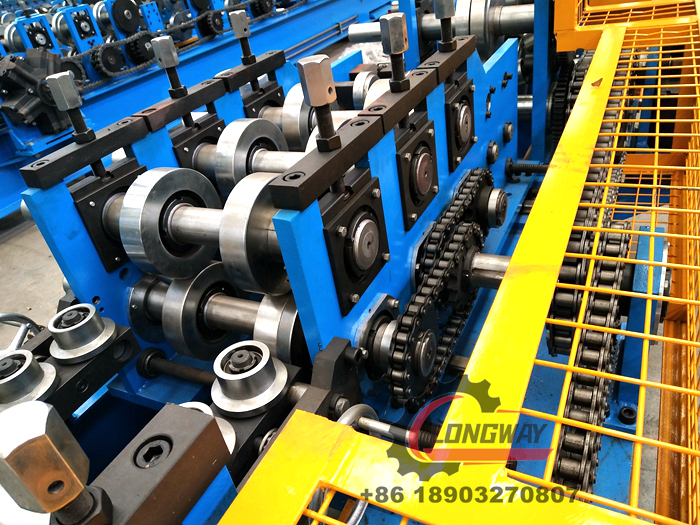

custom roll forming machine factory

Custom roll forming machines have revolutionized the manufacturing sector, providing unparalleled precision, efficiency, and flexibility. These machines are indispensable for industries that require customized metal components in various shapes and sizes. As someone who has spent years working closely with these machines, I aim to convey firsthand insights into their evolving landscape, their manufacturing precision, and the benefits they impart to the industries they serve.

Establishing authority in the field involves continuous research and development. Cutting-edge factories actively engage in R&D to stay abreast of technological advancements and industry trends. For instance, innovations in roll forming techniques that allow the integration of additional processes like punching, notching, and welding directly on the machine have proven to increase efficiency significantly. Factories that lead in innovation can cater to diverse and complex requests, setting themselves apart from competitors. Trustworthiness is paramount when selecting a custom roll forming machine factory. This quality is reflected not only in the durability and reliability of the machines but also in the strength of the relationship between the factory and its clients. A trusted manufacturer provides comprehensive support, from initial consultation through to after-sales service. This includes assistance with installation, maintenance, and technical training. Building a reputation for reliability can often rely on customer testimonials and case studies that evidence past successes and the factory’s commitment to quality. Moreover, the environmental impact of manufacturing processes has become a critical consideration. Leading factories incorporate sustainable practices—such as using energy-efficient machines, recycling waste materials, and minimizing emissions—to align with global environmental standards. This commitment to sustainability not only reflects responsibility but also adds another layer of trust for prospective clients. In summary, the world of custom roll forming machine manufacturing is one underscored by precise engineering, relentless innovation, and a steadfast dedication to quality. Factories dedicated to this craft are characterized by their expertise in customization, authority in technological advancement, and an unwavering commitment to trust and sustainability. They serve as essential partners for any business seeking to advance its production capabilities, maintain competitive edges, and meet the complex demands of today’s industrial marketplace. By integrating these principles, a custom roll forming machine factory not only meets but often exceeds the expectations of its varied clientele.

Establishing authority in the field involves continuous research and development. Cutting-edge factories actively engage in R&D to stay abreast of technological advancements and industry trends. For instance, innovations in roll forming techniques that allow the integration of additional processes like punching, notching, and welding directly on the machine have proven to increase efficiency significantly. Factories that lead in innovation can cater to diverse and complex requests, setting themselves apart from competitors. Trustworthiness is paramount when selecting a custom roll forming machine factory. This quality is reflected not only in the durability and reliability of the machines but also in the strength of the relationship between the factory and its clients. A trusted manufacturer provides comprehensive support, from initial consultation through to after-sales service. This includes assistance with installation, maintenance, and technical training. Building a reputation for reliability can often rely on customer testimonials and case studies that evidence past successes and the factory’s commitment to quality. Moreover, the environmental impact of manufacturing processes has become a critical consideration. Leading factories incorporate sustainable practices—such as using energy-efficient machines, recycling waste materials, and minimizing emissions—to align with global environmental standards. This commitment to sustainability not only reflects responsibility but also adds another layer of trust for prospective clients. In summary, the world of custom roll forming machine manufacturing is one underscored by precise engineering, relentless innovation, and a steadfast dedication to quality. Factories dedicated to this craft are characterized by their expertise in customization, authority in technological advancement, and an unwavering commitment to trust and sustainability. They serve as essential partners for any business seeking to advance its production capabilities, maintain competitive edges, and meet the complex demands of today’s industrial marketplace. By integrating these principles, a custom roll forming machine factory not only meets but often exceeds the expectations of its varied clientele.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products