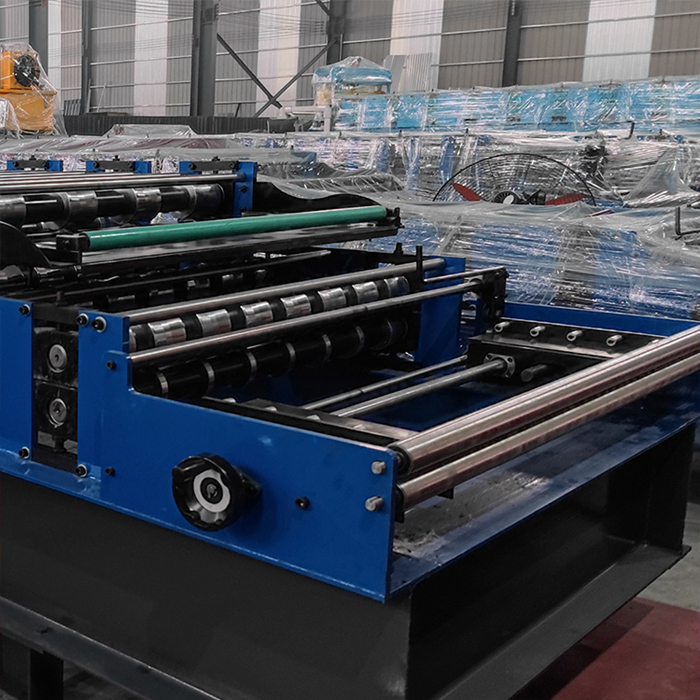

automatic steel sheet slitting line factory

The Evolution of Automatic Steel Sheet Slitting Line Factories

In the world of manufacturing, the efficiency and precision of production lines are paramount to meeting the growing demands for high-quality steel products. This is where automatic steel sheet slitting lines come into play, revolutionizing the way steel sheets are processed. These factories are designed to ensure that steel sheets are cut to desired widths while maintaining consistent quality, speed, and safety. In this article, we will explore the significance, components, advantages, and future of automatic steel sheet slitting line factories.

Understanding Steel Sheet Slitting Lines

Steel sheet slitting is the process of cutting large coils of steel into narrower strips, which can then be used for various applications ranging from automotive parts to construction materials. Traditional methods of slitting involved painstaking manual processes, which were not only time-consuming but also prone to human error. The advancement of technology has led to the development of automatic slitting lines that significantly enhance productivity and ensure uniformity.

Key Components of Automatic Slitting Lines

An automatic steel sheet slitting line consists of several integral components that work together seamlessly.

1. Coil Unwinding System This is the starting point of the slitting line. The steel coil is mounted, and the material is unwound for processing.

2. Leveling Machine Before slitting, the steel sheet is leveled to eliminate any waviness or imperfections. This is crucial for ensuring precise cuts.

3. Slitting Machine This is the core of the operation. The slitting machine employs sharp blades to slice the material into pre-defined widths. The blades can be adjusted depending on the requirements and are designed to maintain sharpness for quality performance.

4. Rewind Section After slitting, the narrower strips of steel are wound onto new cores, ready for transportation or further processing. This section ensures that the strips are neatly coiled and can be handled easily.

Advantages of Automatic Steel Sheet Slitting Lines

automatic steel sheet slitting line factory

The transition to automatic steel sheet slitting lines has brought numerous advantages, making them a preferred choice for manufacturers.

1. Increased Productivity Automatic slitting lines can operate at higher speeds compared to manual processes. This ensures that more sheets are processed within a shorter time frame, leading to enhanced output.

2. Consistency and Quality Automation minimizes human error, leading to uniformity in product quality. The precision of automated systems ensures that each strip is cut to exact specifications, meeting industry standards.

3. Labor Cost Reduction With automation, the reliance on manual labor decreases, allowing companies to reduce labor costs. Operators can focus on monitoring and maintaining the machinery rather than performing repetitive tasks.

4. Flexibility Modern slitting lines can handle various types of steel sheets, including different thicknesses and grades. This flexibility allows manufacturers to cater to diverse market demands without significant downtime for adjustments.

5. Safety Features Automated systems incorporate numerous safety protocols, reducing the risk of workplace accidents. Operators can work from a secure distance while ensuring that machines are functioning properly.

Future Trends in Steel Sheet Slitting Technology

As the manufacturing sector continues to innovate, the future of automatic steel sheet slitting lines looks promising. The integration of artificial intelligence and machine learning is poised to enhance operational efficiency further. Predictive maintenance systems can foresee equipment failures and minimize unscheduled downtimes, ensuring that production remains uninterrupted.

Additionally, the trend towards sustainable manufacturing is pushing factories to adopt greener technologies. Utilizing renewable energy sources and minimizing waste through recycling systems are likely to become standard practices in steel production.

Conclusion

Automatic steel sheet slitting line factories represent a significant leap forward in the manufacturing landscape. With their ability to deliver high-quality products efficiently and safely, these systems are essential in meeting the demands of modern industries. As technology continues to advance, we can anticipate even greater efficiency, flexibility, and sustainability within the slitting line sector, further solidifying its role in the steel manufacturing process. The future is bright for automatic steel sheet slitting lines, as they adapt to the evolving needs of the global market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025