wall panel roll forming machine manufacturer

When it comes to modern construction and interior design, wall panels have gained immense popularity due to their aesthetic appeal, functional benefits, and ease of installation. A key component in the production of these innovative solutions is the wall panel roll forming machine, which has revolutionized the way wall panels are manufactured. In this article, we will explore the features and advantages of wall panel roll forming machines, as well as the role of manufacturers in this industry.

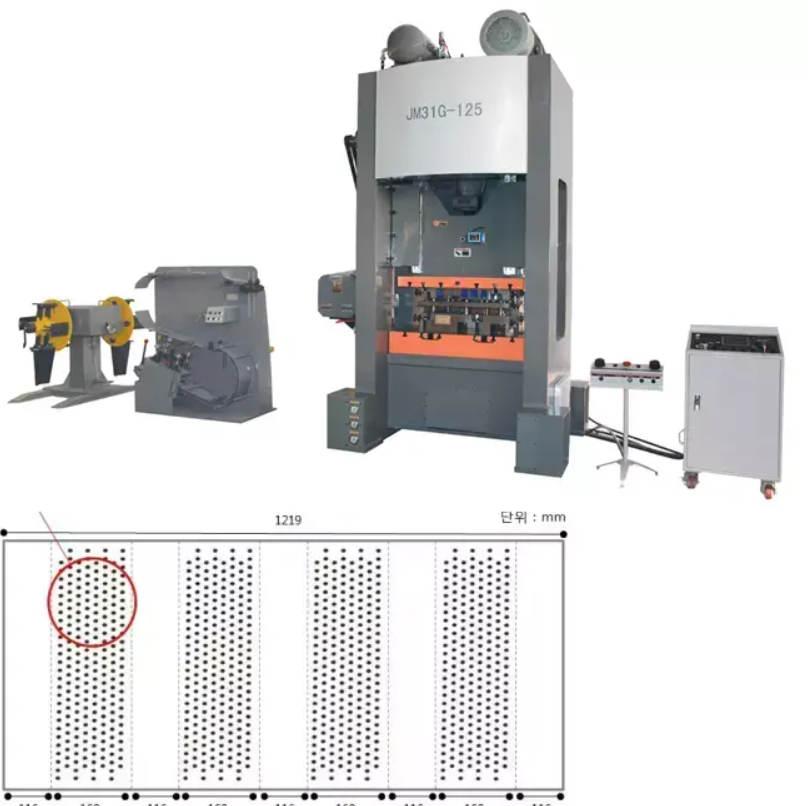

A wall panel roll forming machine is specifically designed to create various types of wall panels from a continuous coil of metal or other materials. The process begins with feeding the raw material into the machine, where it undergoes a series of shaping and forming steps. This method ensures consistency in size and quality, allowing manufacturers to produce panels that meet specific design specifications. The end products can vary widely—from insulated panels that provide thermal efficiency to decorative panels that enhance the visual appeal of structures.

One of the primary advantages of using a wall panel roll forming machine is efficiency. Traditional methods of panel production can be time-consuming and labor-intensive. In contrast, roll forming technology automates much of the process, significantly reducing production time and minimizing human error. Manufacturers can produce large quantities of panels at a fraction of the time and cost compared to conventional methods. This efficiency not only boosts productivity but also allows for competitive pricing in the marketplace.

wall panel roll forming machine manufacturer

Moreover, wall panel roll forming machines are highly versatile. They can be customized to create panels of various sizes, shapes, and profiles, catering to the diverse needs of architects and builders. Whether it's a sleek, modern finish or a more traditional look, these machines can adapt to meet the specific requirements of a project. This flexibility makes them an invaluable asset for manufacturers looking to broaden their product offerings and stay ahead of industry trends.

Quality control is another significant aspect of wall panel production. Leading manufacturers ensure that their roll forming machines are equipped with advanced quality assurance features. This includes sensors and automated systems that monitor the production process, ensuring that each panel meets rigorous standards. By investing in high-quality machinery, manufacturers can dramatically reduce waste and returns, further enhancing their operational efficiency.

In conclusion, wall panel roll forming machines are at the forefront of modern construction and design, providing manufacturers with the ability to produce high-quality, efficient, and customizable wall panels. As the demand for innovative and sustainable building materials continues to grow, these machines play a crucial role in facilitating advancements in the industry. Consequently, choosing a reputable manufacturer of wall panel roll forming machines can significantly impact the success of construction projects, allowing builders to meet both aesthetic and functional requirements with ease.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025