track roll forming machine manufacturers

Track Roll Forming Machine Manufacturers An Overview

In the world of manufacturing, efficiency and precision are paramount. One of the key technologies that have revolutionized various industries is roll forming. Among the specialized equipment in this category, track roll forming machines stand out, particularly in the production of high-quality tracks used in various applications such as automotive processes, construction, and even rail systems. As demand for these machines grows, understanding the role of track roll forming machine manufacturers becomes crucial.

What is Track Roll Forming?

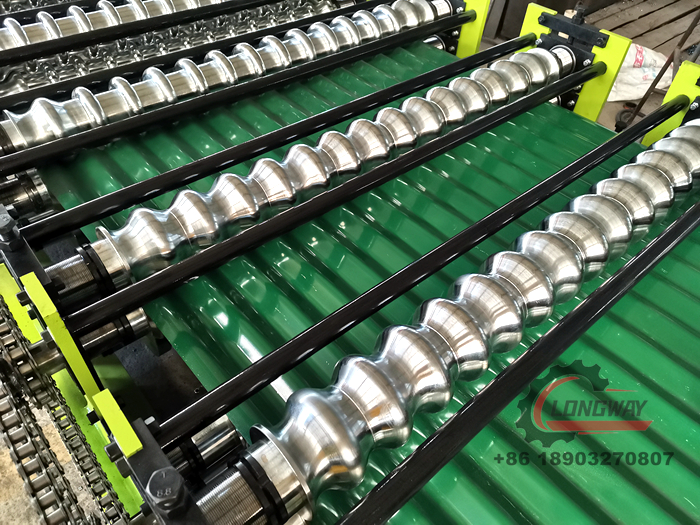

Track roll forming is a continuous metal forming process that involves passing a strip of metal through a series of rollers. These rollers gradually shape the metal into a desired profile—such as tracks used for heavy machinery or transportation systems. The process is known for its ability to produce consistent cross-sections and can be particularly efficient, minimizing waste while maximizing output.

The Importance of Track Roll Forming Machine Manufacturers

Custom track roll forming machines are essential for industries that require specialized profiles. Manufacturers of these machines play a crucial role in the circular economy, contributing to sustainability through efficient production techniques. They provide not only the machinery but also the expertise needed to customize machines for specific applications. A good manufacturer will offer designs that incorporate the latest technologies, ensuring that the machines are capable of delivering high precision and repeatability.

Market Needs and Trends

As construction and automotive industries continue to evolve, there is a growing demand for more sophisticated track roll forming machines. Manufacturers are increasingly focusing on automation, digital control systems, and integration with Industry 4.0 technologies. These advancements contribute to lower operational costs, higher production rates, and improved reliability.

Moreover, with the global push towards sustainability and energy efficiency, manufacturers are also developing machines that use eco-friendly materials and energy-efficient operations. This trend reflects a broader move within the manufacturing sector to meet environmental regulations and consumer expectations, leading to an increased need for innovation among track roll forming machine manufacturers.

Key Players in the Industry

track roll forming machine manufacturers

There are numerous manufacturers around the globe specializing in track roll forming machines. Some companies have established a strong reputation for quality and innovation. These manufacturers typically offer a range of services, including designing custom solutions, providing high-quality machinery, and offering ongoing support and maintenance services.

Factors to Consider When Choosing a Manufacturer

When selecting a track roll forming machine manufacturer, several factors should be taken into account

1. Experience and Reputation Look for manufacturers with a proven track record in the industry. Established companies are likely to have a wealth of experience and customer testimonials.

2. Customization Capabilities It's vital to choose a manufacturer who can tailor their machines to your specific needs, considering factors like material type, profile complexity, and production volume.

3. Technology and Innovation Select a manufacturer that invests in research and development. This is crucial for ensuring that the machines incorporate the latest advancements in efficiency, safety, and usability.

4. Customer Support and Service Reliable after-sales service, maintenance support, and training can make a significant difference in the overall operational efficiency of the machinery.

5. Sustainability Practices Opt for manufacturers who prioritize sustainable practices in their manufacturing processes and products. This not only helps meet regulations but can enhance your own company’s sustainability goals.

Conclusion

Track roll forming machines play an indispensable role in modern manufacturing processes, providing essential solutions for various industries. As the landscape evolves, so too must the manufacturers of these machines. By focusing on innovation, customization, and sustainability, track roll forming machine manufacturers can meet the growing demand for high-quality, efficient, and environmentally friendly solutions. For businesses looking to invest in these valuable assets, careful consideration in selecting the right manufacturer will pave the way for successful operations and competitiveness in the market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025