t18 metal rooofing sheet roll forming machine manufacturers

The Rise of T18 Metal Roofing Sheet Roll Forming Machines

In today's industrial landscape, the demand for high-quality construction materials, especially roofing solutions, has seen a significant surge. One of the standout innovations in this sector is the T18 metal roofing sheet roll forming machine. This specialized equipment is designed to produce T18 metal roofing sheets that are renowned for their durability, aesthetic appeal, and versatility. This article will explore the features and benefits of T18 metal roofing sheet roll forming machines, along with insights into leading manufacturers in this field.

What is T18 Metal Roofing?

T18 metal roofing sheets are a type of profiled sheet that features a distinctive 18mm rib height. They are primarily made from galvanized steel or aluminum and are utilized in various applications, including residential, commercial, and industrial roofing. Their design not only enhances the structural integrity of buildings but also provides excellent weather resistance and thermal insulation.

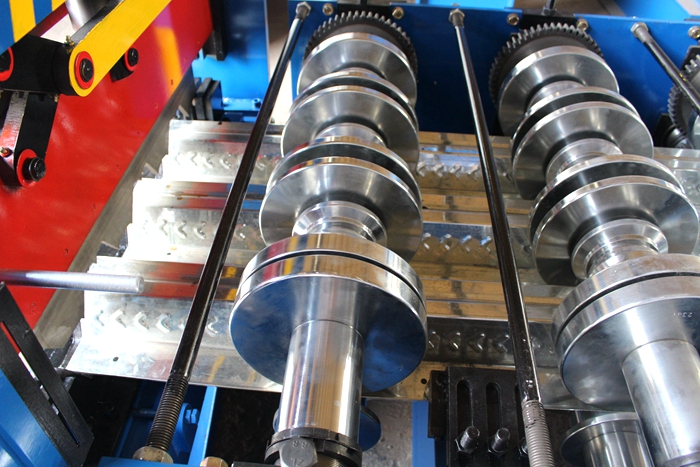

Importance of Roll Forming Machines

Roll forming machines are essential in the production of metal roofing sheets, converting flat metal coils into beautifully shaped profiles through a continuous bending operation. The precision and efficiency of these machines ensure that manufacturers can produce consistent and high-quality sheets at scale. The T18 roll forming machine is particularly valued due to its ability to create sheets with precise dimensions and features that meet specific industry standards.

Key Features of T18 Roll Forming Machines

1. High Efficiency T18 roll forming machines operate at high speeds while maintaining precision, reducing production time and labor costs. 2. Durability Built with robust materials, these machines are designed to withstand the rigors of continuous operation, ensuring longevity and reliability.

3. Customizability Many manufacturers offer customizable options, allowing businesses to adjust the machine specifications according to their specific needs, including the ability to produce various sheet lengths and thicknesses.

4. User-Friendly Interface Modern T18 metal roofing sheet roll forming machines come equipped with intuitive control systems, making it easy for operators to monitor and adjust settings as needed.

5. Automated Features Advanced machines include automated functionalities for material feeding, cutting, and stacking, which enhance efficiency and reduce manual labor.

Benefits of Using T18 Metal Roofing Sheets

t18 metal rooofing sheet roll forming machine manufacturers

1. Cost-Effective Utilizing T18 metal roofing sheets can significantly lower overall construction costs due to their durability and low maintenance requirements. 2. Energy Efficiency With superior insulation properties, these roofing sheets contribute to better energy conservation in buildings, resulting in lower heating and cooling costs.

3. Aesthetic Versatility Available in various colors and finishes, T18 metal roofing sheets can complement any architectural style, making them a popular choice among builders and architects.

4. Sustainability Metal roofing promotes sustainability as it is often composed of recycled materials and is fully recyclable at the end of its life cycle.

Leading Manufacturers

The market for T18 metal roofing sheet roll forming machines is home to numerous manufacturers, each competing to offer the most advanced technology. Notable companies include

- KRM Group Known for their innovative designs and high production efficiency, KRM Group has become a trusted name in metal forming machines globally.

- BlueScope Steel With a deep heritage in the steel industry, BlueScope Steel provides machines that are precision-engineered for the T18 profile, ensuring high-quality material outputs.

- Nuku Mfg. Focused on customer service and customization, Nuku Mfg. has made significant strides in the roll forming equipment market, emphasizing flexibility in production.

- China Roll Forming Machine Manufacturer Many companies based in China have started to dominate the market due to their competitive pricing while maintaining quality standards, offering a wide range of roll forming solutions including T18 machines.

Conclusion

The T18 metal roofing sheet roll forming machine has revolutionized the way metal roofing sheets are produced. Its efficiency, customizability, and the superior quality of the final product make it an indispensable tool for manufacturers. As the construction industry continues to evolve, the importance of such innovative machinery will only grow, thereby contributing to the development of sustainable and cost-effective construction practices. Whether you're a builder, architect, or a construction business owner, investing in T18 metal roofing sheet roll forming machines could be a game-changer for your projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025