18% Metal Roofing Sheet Roll Forming Machine for Efficient Steel Production Solutions

The Advanced Technology of T18 20 Metal Roofing Sheet Roll Forming Machine

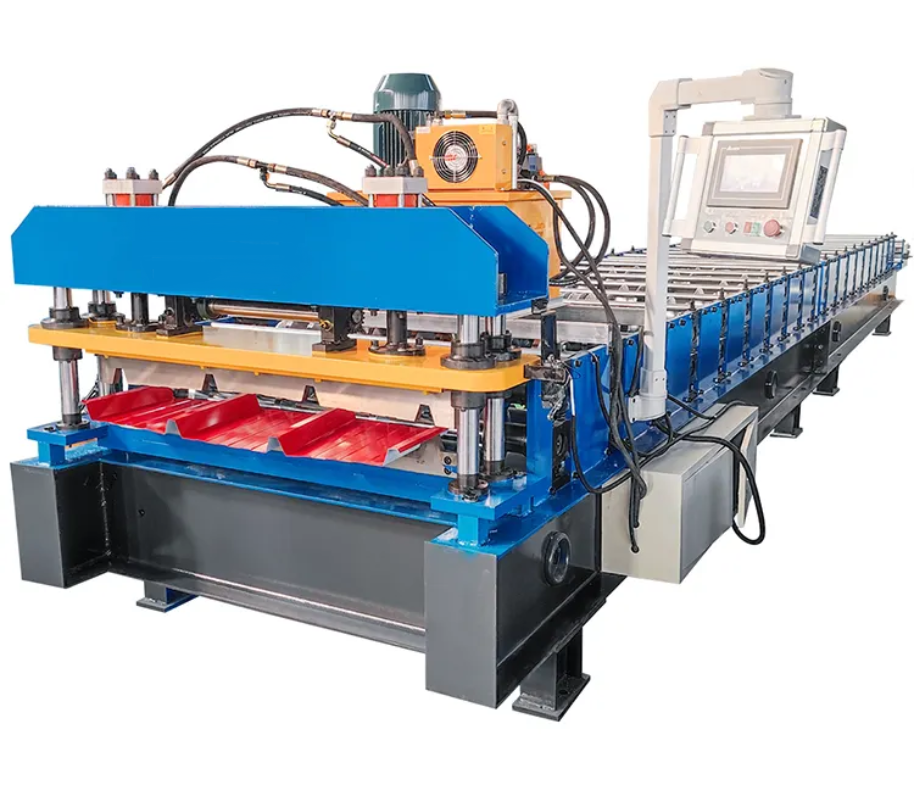

In the ever-evolving construction industry, the demand for durable and efficient building materials is at an all-time high. One of the most significant innovations that have emerged to meet this demand is the T18 20 metal roofing sheet roll forming machine. This cutting-edge machinery plays a vital role in the prefabrication of metal roofing sheets, which are increasingly favored for their longevity, aesthetic appeal, and energy efficiency.

Understanding T18 20 Metal Roofing Sheets

The term T18 refers to a specific profile of metal roofing sheets that feature 18 waves or ribs across their surface, creating a distinctive appearance while enhancing structural integrity. These sheets are often made from high-quality steel, aluminum, or galvanized materials, ensuring they withstand various weather conditions, such as heavy rain, snow, and strong winds. The 20 in the machine's name typically signifies the thickness of the sheets, which usually ranges around 20 gauge, ensuring strength and reliability.

The Process of Roll Forming

The T18 20 metal roofing sheet roll forming machine operates on a sophisticated roll forming process. This method involves the continuous shaping of metal coils into desired profiles through a series of rollers. The machine takes a flat metal sheet and gradually, through various stages of bending and folding, transforms it into the ribbed T18 profile.

1. Feeding The process starts with feeding a flat metal coil into the machine. 2. Forming As the coil passes through various sets of rollers, it's continuously shaped into the T18 profile. The precision engineering of the rollers ensures uniformity in width, height, and pitch. 3. Cutting Once the desired length of the roofing sheet is achieved, a cutting mechanism slices the sheet off from the coil. 4. Finishing The final stage may include the application of protective coatings or paints, enhancing both the durability and visual appeal of the metal sheets.

Advantages of T18 20 Metal Roofing Sheets

1. Durability Metal roofing sheets are designed to last for decades, often up to 50 years or more, with minimal maintenance required. They are resistant to rot, pests, and extreme weather.

t18 metal roofing sheet roll forming machine

2. Lightweight Compared to traditional roofing materials like tiles or concrete, metal sheets are significantly lighter, which can facilitate easier handling and installation.

3. Energy Efficiency Many metal roofing systems can be treated to reflect solar energy, thereby reducing heat absorption. This characteristic can lead to lower energy costs and a more comfortable indoor environment.

4. Aesthetic Versatility T18 metal roofing sheets come in various colors and finishes, allowing homeowners and builders to select an option that complements their architectural style.

5. Sustainability Metal roofing is often made from recycled materials and is fully recyclable at the end of its life cycle, making it an environmentally friendly choice for building projects.

Applications

The T18 20 metal roofing sheet roll forming machine is suited for various applications, ranging from residential roofing to commercial and industrial buildings. Its versatility also extends to agricultural buildings and storage facilities, where robust and weather-resistant roofing is essential.

Conclusion

The introduction of the T18 20 metal roofing sheet roll forming machine has revolutionized the manufacturing of metal roofing materials. By utilizing advanced technology to produce durable and aesthetically pleasing roofing solutions, this machine exemplifies the innovation that continues to drive the construction industry forward. As more builders and homeowners recognize the advantages of metal roofing, it is clear that machines like the T18 20 will play a crucial role in shaped the future of construction, ensuring that buildings are not only resilient but also energy-efficient and visually appealing. As we move into a more sustainable future, the benefits of investing in such technology will be felt across our communities and buildings for generations to come.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025