sheet metal roll forming

Sheet Metal Roll Forming An Overview

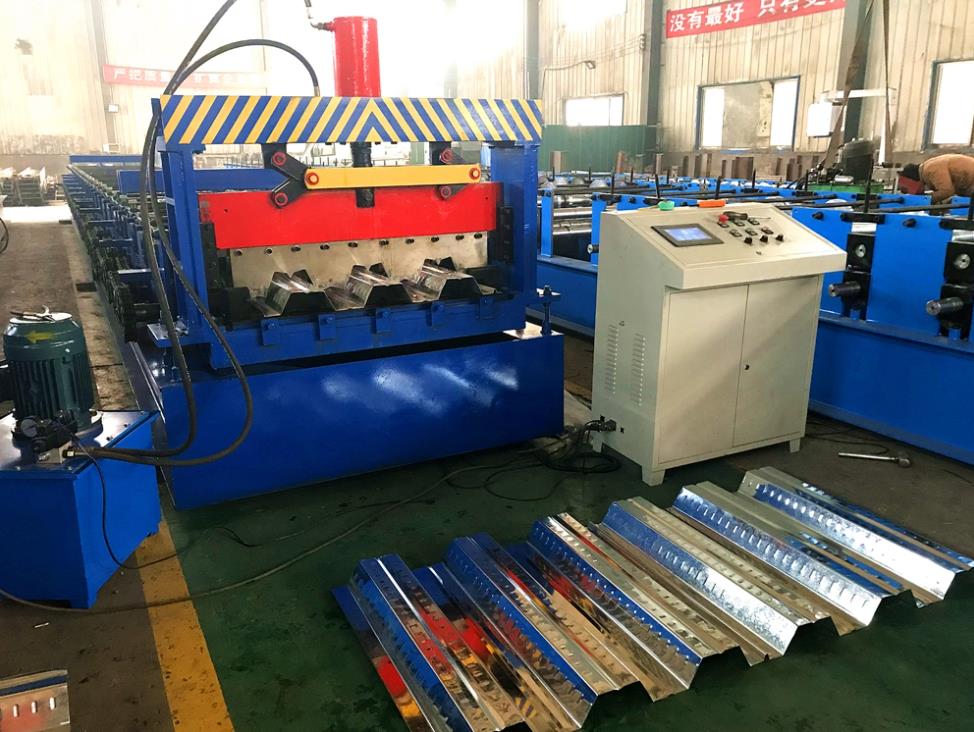

Sheet metal roll forming is a highly efficient manufacturing process used to create continuous lengths of metal profiles from flat sheets of metal. This technique is particularly valued in industries such as construction, automotive, and appliance manufacturing due to its ability to produce complex shapes with high precision and uniformity. Understanding the fundamentals of roll forming, its advantages, and its applications can provide valuable insights into its significance in modern manufacturing.

The Roll Forming Process

Roll forming involves feeding a flat strip of metal through a series of rollers that gradually shape the material into the desired profile. The process begins with a metal coil, which is uncoiled and guided through a series of rollers, each carefully designed to incrementally bend the metal into the final shape. This continuous forming technique allows for the production of long lengths of product without the interruptions typically associated with other forming processes.

One of the key advantages of roll forming is its ability to produce complex cross-sectional shapes with minimal material wastage. The process can create various profiles, such as C channels, Z sections, and even unique custom shapes tailored to specific applications. The consistency and repeatability of the roll forming process make it an ideal choice for mass production, ensuring that each piece meets stringent quality standards.

Advantages of Sheet Metal Roll Forming

Roll forming offers several compelling benefits over other metal forming methods. Firstly, the speed of production is a notable advantage. Once the tooling is set up, the process can produce continuous lengths of formed metal at a rapid pace. This efficiency not only reduces manufacturing times but also lowers labor and operational costs.

sheet metal roll forming

Additionally, roll forming is versatile in terms of material compatibility. It can accommodate a range of metals, including aluminum, stainless steel, and galvanized steel. This versatility enables manufacturers to select materials that best suit their specific needs, whether for strength, weight, or corrosion resistance.

Another significant benefit is the high level of accuracy and consistency achieved through the roll forming process. The precision of the rollers and the controlled conditions allow for tight tolerances in dimensions, making it possible to produce parts that fit together seamlessly in assemblies.

Applications of Roll Forming

Due to its advantages, sheet metal roll forming finds applications across various industries. In construction, roll-formed components are commonly used for roofing systems, wall panels, and structural supports. The automotive industry utilizes roll forming to manufacture components like car door frames, bumpers, and structural reinforcements, capitalizing on the process’s strength and lightweight characteristics.

Moreover, the appliance industry also benefits from roll forming in creating parts for washers, dryers, and refrigerators. With the growing emphasis on energy efficiency and sustainability, roll-formed parts can be designed to enhance the performance of appliances while reducing overall material use.

Conclusion

In conclusion, sheet metal roll forming is a vital process in manufacturing that provides efficiency, precision, and versatility. Its ability to produce complex shapes with minimal waste makes it an essential technique in various industries. As technology continues to evolve, the applications and capabilities of roll forming are likely to expand, further solidifying its role in the modern manufacturing landscape. Whether for structural components or intricate designs, roll forming remains an indispensable method for shaping metal into functional and innovative products.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025