Top Manufacturers of Machinery for Roof Truss Production and Fabrication Solutions

The Rise of Roof Truss Machinery Manufacturers

Roof trusses play a pivotal role in modern construction, supporting the weight of roofing while allowing for spacious interiors without requiring load-bearing walls. As architectural demands evolve, so does the need for advanced machinery that efficiently produces these essential components. Roof truss machinery manufacturers are at the forefront of this evolution, providing innovative solutions that cater to the diverse needs of builders and contractors.

The Importance of Roof Trusses

Roof trusses are engineered frameworks that provide structural support to roofs, enabling architects and builders to design buildings with various shapes and sizes. They consist of triangular units, which distribute weight evenly and allow for greater spans than traditional framing methods. With the growing trend of open-concept living spaces and larger commercial structures, the demand for roof trusses has surged, creating a significant market for manufacturers of roof truss machinery.

Innovations in Machinery

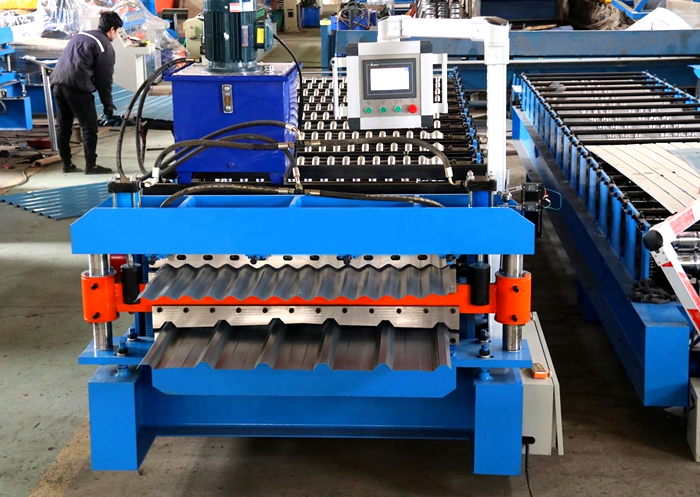

The competitiveness in the construction industry calls for precision and efficiency, making the advancements in roof truss machinery essential. Today's manufacturers are employing state-of-the-art technology, including computer numerical control (CNC) machines and automated fabrication systems. These innovations minimize human error, enhance production speed, and improve the overall quality of the trusses produced.

For instance, CNC machines can accurately cut and assemble various components of a truss, allowing manufacturers to create custom designs that meet specific building codes and customer requirements. Furthermore, automation in production lines enables manufacturers to scale operations, reducing labor costs and increasing output without sacrificing quality.

Sustainable Practices

As environmental concerns continue to shape the construction industry, roof truss machinery manufacturers are also focusing on sustainability. They are adopting practices that reduce waste and promote the use of renewable materials. For example, manufacturers are optimizing their machinery to work with engineered woods and other sustainable materials that are not only eco-friendly but also lightweight and strong.

roof truss machinery manufacturers

Moreover, many manufacturers are incorporating computer-aided design (CAD) and building information modeling (BIM) technologies into their processes, allowing for better planning and resource management. These tools help in analyzing material usage and minimizing waste, leading to more efficient production cycles and environmentally responsible practices.

Global Manufacturer Landscape

The landscape of roof truss machinery manufacturing is diverse, with companies worldwide competing to deliver the best products. In regions like North America and Europe, manufacturers are known for their high-quality machinery that meets stringent safety and building standards. Meanwhile, manufacturers in Asia are gaining traction by offering cost-effective solutions without compromising quality.

Collaborations between manufacturers and technology firms are also on the rise, as producers seek to integrate cutting-edge software and hardware into their machinery. Such partnerships facilitate ongoing innovation, allowing manufacturers to respond dynamically to market demands and technological advancements.

Challenges Ahead

Despite the opportunities in the roof truss machinery sector, challenges persist. The fluctuating prices of raw materials and supply chain issues can impact manufacturing efficiency and costs. Additionally, the industry faces a workforce shortage, as fewer skilled workers are entering the field. Manufacturers are responding by investing in training programs and automation to alleviate these labor challenges.

Furthermore, as the construction industry moves toward modular and prefabricated building methods, roof truss machinery manufacturers must adapt their processes to maintain relevance. Embracing change and innovation will be key to thriving in this rapidly evolving market.

Conclusion

In conclusion, roof truss machinery manufacturers are essential players in the construction landscape. As demand for roof trusses continues to grow, driven by changing architectural trends and increased focus on sustainability, these manufacturers are poised for significant growth. By embracing technological advancements and sustainable practices, they can enhance efficiency, reduce waste, and meet the diverse needs of the modern construction industry. The future looks promising for those who are willing to innovate and adapt in a competitive global environment. With ongoing developments in machine technology and manufacturing processes, roof truss machinery manufacturers will play a vital role in shaping the skylines of tomorrow.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025