студ . 21, 2025 03:44

Back to list

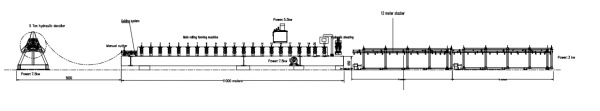

metal roof sheet forming machine

Roof sheet forming machines have revolutionized the construction industry by enabling the rapid production of high-quality roofing materials. These machines are integral for any manufacturer or contractor aiming to improve their operational efficiency and ensure the durability of roofing solutions they provide. But success in using a roof sheet forming machine doesn't solely depend on the machine itself; it also hinges on understanding its function, the benefits it brings, and how to harness its full potential.

Authoritativeness in the field also comes from years of experience and proven results. Building a reputation for reliability and quality in the roof sheet manufacturing industry means delivering on promises consistently. Customer testimonials and case studies can provide potential clients with the assurance needed when choosing a supplier. Demonstrating a strong track record in delivering large projects within deadlines while maintaining high standards is key. Furthermore, industry certifications and affiliations with recognized bodies can lend credibility and assure clients of the commitment to standards and quality. Trustworthiness is equally foundational for manufacturers and suppliers of roof sheet forming machines. Transparency with clients about the capabilities and limitations of machines fosters trust. Providing detailed documentation and support post-purchase—including training sessions, maintenance guides, and reliable troubleshooting services—helps build a long-term relationship with clients. After-sale service is indispensable; clients need assurance in the form of prompt technical support and customer service. In integrating a roof sheet forming machine into a business, it is essential to conduct a comprehensive cost-benefit analysis. This involves comparing the capital investment against anticipated savings in labor, material efficiency, and the increased capacity for projects. Potential buyers should weigh these factors and consider securing machines from reputable suppliers who offer a warranty, proving that they stand by their product. In conclusion, roof sheet forming machines mark a significant milestone towards modernizing roofing processes. While they offer remarkable advantages in terms of precision, efficiency, and versatility, maximizing their benefits entails investing in expertise, maintaining a commitment to quality, and ensuring customer satisfaction through trust and transparent business practices. For businesses in the competitive construction and manufacturing landscape, these principles aren't just optional; they are central to fostering growth and sustaining a leading position in the industry.

Authoritativeness in the field also comes from years of experience and proven results. Building a reputation for reliability and quality in the roof sheet manufacturing industry means delivering on promises consistently. Customer testimonials and case studies can provide potential clients with the assurance needed when choosing a supplier. Demonstrating a strong track record in delivering large projects within deadlines while maintaining high standards is key. Furthermore, industry certifications and affiliations with recognized bodies can lend credibility and assure clients of the commitment to standards and quality. Trustworthiness is equally foundational for manufacturers and suppliers of roof sheet forming machines. Transparency with clients about the capabilities and limitations of machines fosters trust. Providing detailed documentation and support post-purchase—including training sessions, maintenance guides, and reliable troubleshooting services—helps build a long-term relationship with clients. After-sale service is indispensable; clients need assurance in the form of prompt technical support and customer service. In integrating a roof sheet forming machine into a business, it is essential to conduct a comprehensive cost-benefit analysis. This involves comparing the capital investment against anticipated savings in labor, material efficiency, and the increased capacity for projects. Potential buyers should weigh these factors and consider securing machines from reputable suppliers who offer a warranty, proving that they stand by their product. In conclusion, roof sheet forming machines mark a significant milestone towards modernizing roofing processes. While they offer remarkable advantages in terms of precision, efficiency, and versatility, maximizing their benefits entails investing in expertise, maintaining a commitment to quality, and ensuring customer satisfaction through trust and transparent business practices. For businesses in the competitive construction and manufacturing landscape, these principles aren't just optional; they are central to fostering growth and sustaining a leading position in the industry.

Next:

Latest news

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

Related Products