roll forming machine for perfil drywall parante

Roll forming machines play a crucial role in the production of drywall profiles, specifically known as perfiles for constructing drywall partitions. This advanced manufacturing process is tailored to create precise and consistent profiles that are essential for the integrity and durability of drywall constructions.

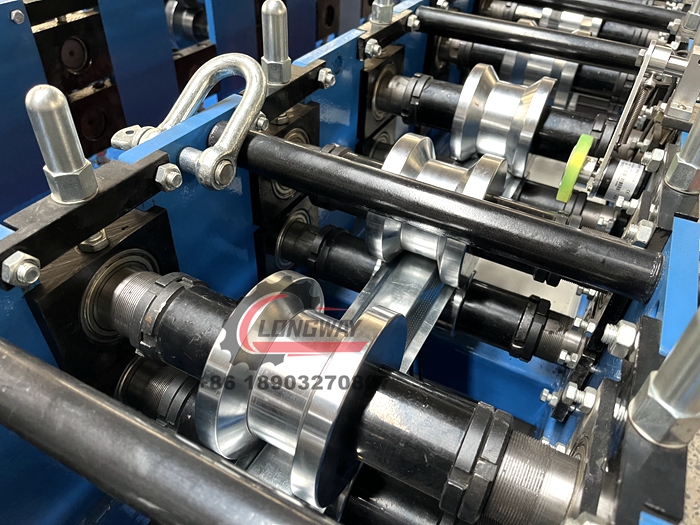

At its core, a roll forming machine continuously bends a long strip of metal, usually steel, into desired cross-sectional shapes. These machines come equipped with multiple sets of rollers, each intricately designed to progressively shape the metal as it passes through. For drywall profiles, these shapes can include C-channels, U-channels, and various other configurations that provide structural support in wall and ceiling systems.

One significant advantage of employing a roll forming machine for manufacturing drywall profiles is the efficiency of the process. Unlike traditional cutting or shaping methods, roll forming allows for high-volume production with minimal waste. The continuous nature of the process means that manufacturers can produce long lengths of profiles without interruptions, significantly enhancing productivity.

Additionally, the precision of roll forming is essential when working with drywall profiles. Consistent dimensions and angles are critical to ensuring that these profiles fit together seamlessly during installation. This level of accuracy not only simplifies the construction process but also ensures that the structural integrity of the drywall system is maintained.

roll forming machine for perfil drywall parante

Another notable benefit is the versatility of roll forming machines. They can be customized to produce a wide range of profile dimensions and shapes, catering to various architectural designs and building requirements. As construction trends evolve, the ability to swiftly adapt production lines means that manufacturers can stay competitive and meet the demands of the market.

Moreover, with advancements in technology, modern roll forming machines often incorporate automation and digital controls. This integration allows for easier adjustments and monitoring of production runs, ultimately leading to enhanced quality control and reduced labor costs.

In conclusion, roll forming machines are an indispensable asset in the manufacturing of drywall profiles. They deliver efficiency, precision, and versatility, making them essential for modern construction practices. As the industry continues to grow, the significance of these machines will undoubtedly remain at the forefront of drywall production.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025