metal roofing trim machine

The Importance of Metal Roofing Trim Machines

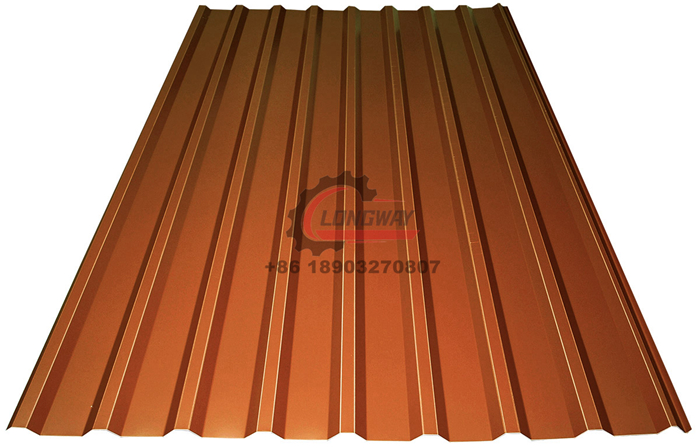

In the construction and roofing industry, the demand for durable and aesthetically pleasing materials is ever-growing. One of the innovations that have significantly enhanced the efficiency and quality of roofing installations is the metal roofing trim machine. These machines are designed to produce metal roofing trims with precision, ensuring that builders can provide robust, weather-resistant, and visually appealing roofs.

Metal roofing has become a popular choice among homeowners and builders alike due to its durability, longevity, and energy efficiency. However, for a metal roof to perform optimally, it requires precise trims and edging. This is where metal roofing trim machines come into play. These machines allow for the quick and accurate production of various trims, including ridge caps, eave trims, and gable trims, which are essential for completing a metal roof installation.

One of the primary advantages of using metal roofing trim machines is the speed at which they operate. Traditional methods of cutting and shaping metal trims can be labor-intensive and time-consuming. In contrast, these machines automate the process, significantly reducing the time required to produce high-quality trims. This efficiency not only speeds up the installation process but also helps in managing costs, making projects more profitable for contractors.

metal roofing trim machine

Moreover, the precision offered by metal roofing trim machines is unparalleled. Manual cutting often leads to inconsistencies, which can compromise the integrity and appearance of the roof. Machines designed for this purpose ensure that each trim piece is uniform and accurately cut to specification. This precision results in a better fit and finish, contributing to the overall aesthetic appeal of the roofing system while enhancing its performance in adverse weather conditions.

Another critical aspect is the versatility of modern metal roofing trim machines. Many of these machines are capable of producing trims in various styles and materials, allowing builders to cater to different architectural designs and customer preferences. This versatility not only expands a contractor’s offerings but also allows for custom solutions that meet specific client needs.

Sustainability is another significant benefit of using metal roofing trim machines. Metal roofing materials are often recyclable, and the precise cutting allows for minimizing waste. By optimizing material usage, these machines promote environmental sustainability within the construction process, aligning with the increasing demand for eco-friendly building practices.

In conclusion, the advent of metal roofing trim machines has revolutionized the roofing industry. These machines enhance efficiency, precision, and sustainability, enabling builders to deliver high-quality metal roofing solutions that meet modern building standards. As the demand for metal roofing continues to rise, investing in advanced trim machines becomes more critical than ever. By integrating these technologies into their workflow, contractors can improve their operational capabilities, satisfy their clients, and maintain a competitive edge in the market. Whether for residential projects or commercial roofing installations, the role of metal roofing trim machines cannot be underestimated.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025