Corrugated Metal Sheet Manufacturing Machine Supplier and Production Solutions

Revolutionizing the Industry The Role of Machinery in Corrugated Metal Sheet Manufacturing

The manufacturing of corrugated metal sheets has evolved significantly over the years, driven by advancements in technology and machinery. These metal sheets, often used in construction, roofing, and various industrial applications, are favored for their strength, durability, and lightweight properties. A key player in this transformation is the modern machine designed specifically for producing corrugated metal sheets. This article explores the various aspects of corrugated metal sheet manufacturing and the pivotal role that specialized machinery plays in enhancing efficiency and quality.

Understanding Corrugated Metal Sheets

Corrugated metal sheets are typically made from steel, aluminum, or even copper, and are characterized by their wave-like patterns. This design not only adds to the aesthetic appeal but also improves the structural integrity of the sheets, providing resistance against various weather conditions. These sheets are widely used in commercial buildings, warehouses, and even residential projects, offering an economical solution for roofing and wall cladding.

The Importance of Advanced Machinery

Increased demand for corrugated metal sheets has led manufacturers to adopt advanced machinery to streamline production processes. These machines are designed to perform specific tasks such as cutting, bending, and shaping metal sheets into their desired forms. The integration of computerized controls and automation has significantly enhanced production rates while reducing labor costs.

Types of Machinery in Corrugated Metal Sheet Production

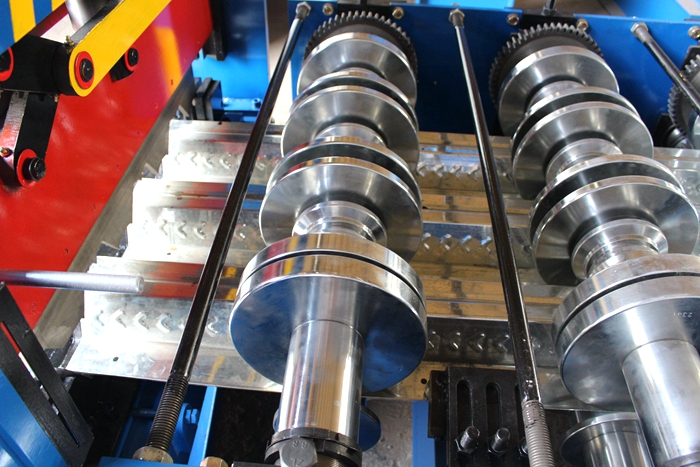

1. Roll Forming Machines These are fundamental in the production of corrugated metal sheets. The roll forming process involves passing a metal strip through a series of rollers, each of which shapes the metal into progressively more complex profiles. This method ensures consistency in the thickness and quality of the sheets, enabling manufacturers to produce large quantities without compromising quality.

2. Shearing Machines Accurate cutting of metal sheets is essential in the manufacturing process. Shearing machines are equipped with sharp blades that can cut through metal with precision. The ability to customize the size of the sheets according to client specifications is a significant advantage, allowing for flexibility in production.

3. Press Brakes For manufacturers looking to create unique shapes and designs, press brakes are indispensable. These machines can bend metal sheets to specific angles and shapes, providing the versatility needed to cater to diverse architectural demands.

machine to make corrugated metal sheet manufacturer

4. Coating Machines The durability of corrugated metal sheets can be enhanced through various coating techniques, such as galvanizing or painting. Coating machines apply protective layers to the sheets, ensuring they withstand corrosion and extending their lifespan.

Advantages of Modern Machinery

Investing in advanced machinery for corrugated metal sheet production brings a multitude of benefits

- Increased Efficiency Automated machinery operates at a much faster pace than traditional manual methods. This increased speed allows manufacturers to keep up with rising market demands, ultimately enhancing productivity.

- Cost-Effectiveness Although the initial investment in modern machines may be substantial, the long-term savings are significant. Higher efficiency means lower labor costs and reduced waste, translating to better profit margins.

- Consistent Quality Advanced machines can achieve precise measurements and uniformity in production, ensuring that every sheet meets the required specifications. Consistency is vital for building projects, where quality control is paramount.

- Customization Modern machinery allows manufacturers to offer tailored solutions to their clients. Whether it’s custom sizes, profiles, or finishes, the flexibility of new machines can meet diverse client needs.

Conclusion

The shift to modern machinery in the manufacturing of corrugated metal sheets has revolutionized the industry. As technology continues to evolve, manufacturers who embrace these advancements are better positioned to compete in an increasingly demanding market. The future of corrugated metal sheet production lies in leveraging innovative machinery to achieve greater efficiency, quality, and customization, ensuring that this essential material continues to play a pivotal role in construction and industrial applications around the globe. As the industry progresses, it is clear that machinery is not just a tool; it is a catalyst for growth and innovation in the realm of corrugated metal sheet manufacturing.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025