лют . 16, 2025 16:26

Back to list

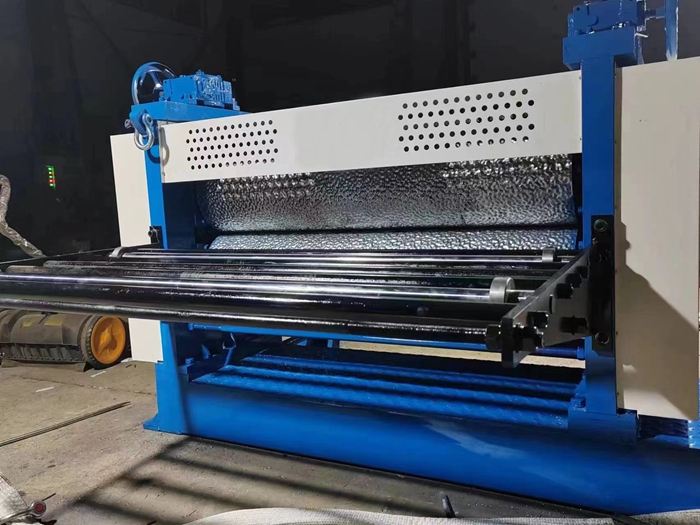

door frame roll forming machine price

Investing in a door frame roll forming machine is a significant decision for manufacturers aiming to scale production and enhance precision. Understanding the pricing dynamics of these machines is crucial to making informed purchasing decisions. This article delves into factors affecting the price of door frame roll forming machines, offering insights drawn from real-world experiences and industry expertise.

Customization is another aspect affecting the cost of door frame roll forming machines. Companies with specific production needs may require custom designs to align with their operational goals. Such bespoke solutions often involve additional engineering, design, and testing processes, understandably reflecting in higher prices. Nonetheless, custom machines can deliver enhanced performance tailored to unique production challenges, which is invaluable in competitive markets. The geographical location of the manufacturer and the machine supplier can impact pricing due to logistical and tax considerations. Importing machinery might add significant costs related to shipping, customs, and import duties. However, this can be mitigated by sourcing from local suppliers, which sometimes offer competitive pricing and quicker access to support and services. Cost efficiency can also be achieved by analyzing the machine’s energy consumption. Sustainable and energy-efficient designs, while potentially pricier initially, can lead to substantial savings over the machine's lifespan. With increasing demand for eco-friendly manufacturing solutions, investing in green technology not only reduces operational costs but also positions manufacturers as responsible and forward-thinking in the eyes of environmentally conscious stakeholders. Finally, warranty and post-sale services form critical components of the overall price. A higher-priced roll forming machine often comes with extended warranties and comprehensive support services, ensuring minimal downtime and expeditious problem resolution. Users should prioritize these features, as they safeguard the manufacturing process against unforeseen disruptions. In conclusion, when evaluating door frame roll forming machine prices, businesses must consider not just the upfront costs but the broader spectrum of value offered by the machine. Experienced manufacturers leverage their industry expertise to assess automation levels, material capabilities, brand reputations, and service offerings to achieve optimal operational success. By focusing on long-term gains rather than immediate savings, companies can enhance productivity, reduce costs, and retain a competitive edge in the marketplace. Consequently, understanding these nuances is essential for manufacturers aiming to make a well-informed investment in their production capabilities.

Customization is another aspect affecting the cost of door frame roll forming machines. Companies with specific production needs may require custom designs to align with their operational goals. Such bespoke solutions often involve additional engineering, design, and testing processes, understandably reflecting in higher prices. Nonetheless, custom machines can deliver enhanced performance tailored to unique production challenges, which is invaluable in competitive markets. The geographical location of the manufacturer and the machine supplier can impact pricing due to logistical and tax considerations. Importing machinery might add significant costs related to shipping, customs, and import duties. However, this can be mitigated by sourcing from local suppliers, which sometimes offer competitive pricing and quicker access to support and services. Cost efficiency can also be achieved by analyzing the machine’s energy consumption. Sustainable and energy-efficient designs, while potentially pricier initially, can lead to substantial savings over the machine's lifespan. With increasing demand for eco-friendly manufacturing solutions, investing in green technology not only reduces operational costs but also positions manufacturers as responsible and forward-thinking in the eyes of environmentally conscious stakeholders. Finally, warranty and post-sale services form critical components of the overall price. A higher-priced roll forming machine often comes with extended warranties and comprehensive support services, ensuring minimal downtime and expeditious problem resolution. Users should prioritize these features, as they safeguard the manufacturing process against unforeseen disruptions. In conclusion, when evaluating door frame roll forming machine prices, businesses must consider not just the upfront costs but the broader spectrum of value offered by the machine. Experienced manufacturers leverage their industry expertise to assess automation levels, material capabilities, brand reputations, and service offerings to achieve optimal operational success. By focusing on long-term gains rather than immediate savings, companies can enhance productivity, reduce costs, and retain a competitive edge in the marketplace. Consequently, understanding these nuances is essential for manufacturers aiming to make a well-informed investment in their production capabilities.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products