лют . 16, 2025 08:44

Back to list

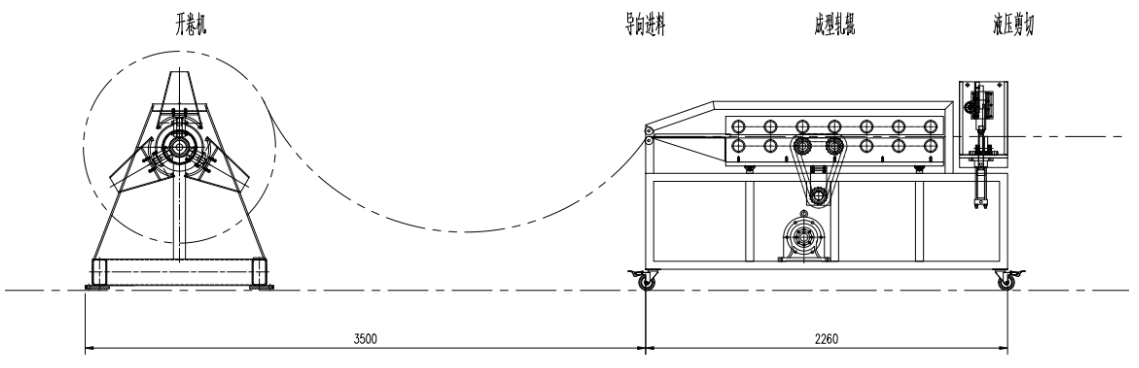

customized purlin roll forming machine

In the world of modern construction and infrastructure development, precision and efficiency are paramount. Customized purlin roll forming machines stand at the intersection of these needs, offering unparalleled adaptability and performance. These machines, integral to the production of structural components, cater to a wide range of applications across industries, underscoring the importance of investing in technologically advanced machinery.

The authority of a customized purlin roll forming machine is realized through its versatility and reliability. These machines boast advanced features such as automated control systems, safety mechanisms, and diagnostic capabilities that alert operators of any potential issues. This authority is bolstered by the machine’s adaptability to various materials, whether producing purlins from galvanized steel, aluminum, or stainless steel. The roll forming process itself is a testament to technological authority; it allows for the continuous production of purlins in a high-speed environment without compromising on quality. Trustworthiness is a key consideration when investing in machinery of this magnitude. Customized purlin roll forming machines, provided by reputable manufacturers, come with comprehensive service agreements and support systems. This ensures that any operational hiccups are swiftly addressed, maintaining the machine's longevity and operational efficiency. Trust is further established through rigorous testing and certification processes that validate the machine’s performance under different operational scenarios. In conclusion, the decision to incorporate a customized purlin roll forming machine into the production line not only reflects a commitment to innovation but also underscores a strategic approach to meeting modern construction demands. The benefits extend beyond mere production efficiency. They encompass enhanced structural viability, cost-effectiveness, and alignment with sustainable practices. As industries continue to evolve, the role of customized roll forming machines will undoubtedly become more prominent, carving a new standard in precision manufacturing. Investing in such machinery is a forward-looking decision that aligns with the evolving landscape of construction technologies, ensuring robust and reliable outcomes across diverse project parameters.

The authority of a customized purlin roll forming machine is realized through its versatility and reliability. These machines boast advanced features such as automated control systems, safety mechanisms, and diagnostic capabilities that alert operators of any potential issues. This authority is bolstered by the machine’s adaptability to various materials, whether producing purlins from galvanized steel, aluminum, or stainless steel. The roll forming process itself is a testament to technological authority; it allows for the continuous production of purlins in a high-speed environment without compromising on quality. Trustworthiness is a key consideration when investing in machinery of this magnitude. Customized purlin roll forming machines, provided by reputable manufacturers, come with comprehensive service agreements and support systems. This ensures that any operational hiccups are swiftly addressed, maintaining the machine's longevity and operational efficiency. Trust is further established through rigorous testing and certification processes that validate the machine’s performance under different operational scenarios. In conclusion, the decision to incorporate a customized purlin roll forming machine into the production line not only reflects a commitment to innovation but also underscores a strategic approach to meeting modern construction demands. The benefits extend beyond mere production efficiency. They encompass enhanced structural viability, cost-effectiveness, and alignment with sustainable practices. As industries continue to evolve, the role of customized roll forming machines will undoubtedly become more prominent, carving a new standard in precision manufacturing. Investing in such machinery is a forward-looking decision that aligns with the evolving landscape of construction technologies, ensuring robust and reliable outcomes across diverse project parameters.

Latest news

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025

Related Products