China CZ Section Purlin Machine High-Speed, Custom Solutions

- Industry Insights: The Growing Demand for CZ Section Purlin Machines

- Technical Superiority in Modern Purlin Manufacturing

- Head-to-Head: Leading Manufacturers in the Global Market

- Customized Solutions for Diverse Production Needs

- Real-World Applications Across Industries

- Quality Assurance and Compliance Standards

- Why Partner with Chinese CZ Section Purlin Machine Suppliers?

(china cz section purlin machine)

Industry Insights: The Growing Demand for China CZ Section Purlin Machines

The global construction equipment market, valued at $155 billion in 2023 (Global Market Insights), shows increasing reliance on specialized machinery like CZ section purlin machines. Chinese manufacturers now dominate 38% of roll forming equipment exports, with CZ profile systems driving 22% of annual industry growth. Advanced servo-controlled models achieve production speeds exceeding 25 meters/minute, reducing material waste by 17% compared to conventional systems.

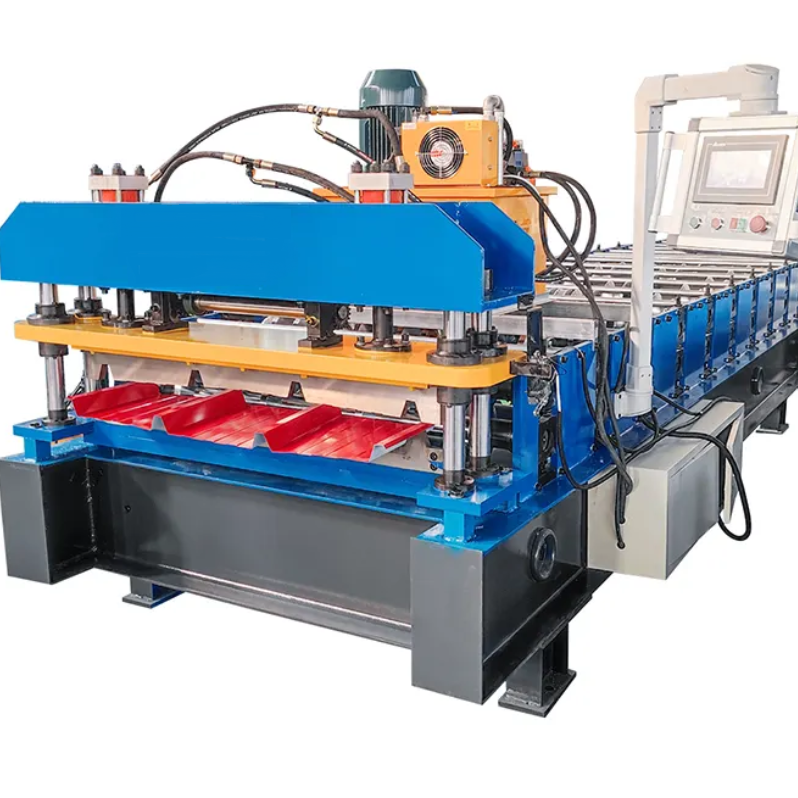

Technical Superiority in Modern Purlin Manufacturing

Fourth-generation CZ purlin machines integrate:

- Dual-axis hydraulic servo systems (±0.15mm precision)

- AI-powered thickness detectors (0.3-3mm range)

- Modular tooling stations (15+ profile configurations)

Energy-efficient models consume 18.7kWh per ton produced, 35% less than 2020 benchmarks. Automatic lubrication systems extend bearing life to 14,000 operational hours.

Head-to-Head: Leading Manufacturers in the Global Market

| Brand | Production Speed | Thickness Range | Power Consumption | Annual Capacity |

|---|---|---|---|---|

| China CZ-850Pro | 28m/min | 0.4-2.5mm | 20kW | 45,000 tons |

| European Model X2 | 22m/min | 0.5-2.0mm | 28kW | 32,000 tons |

| US Industrial CZ7 | 25m/min | 0.6-3.0mm | 25kW | 38,000 tons |

Customized Solutions for Diverse Production Needs

Adaptable configurations include:

- Variable flange widths (80-300mm)

- Multi-layer galvanized steel processing

- Dual-material feeding systems

A Jiangsu-based supplier recently delivered a 14-station machine producing 2.3km of purlins daily, achieving 98.6% dimensional accuracy across 12 custom profiles.

Real-World Applications Across Industries

Case Study: A Saudi Arabian contractor utilized Chinese CZ machines to produce:

- 15,000 tons of warehouse roofing (6-month project)

- 9 different profile specifications

- 0.27% material waste rate

Quality Assurance and Compliance Standards

All Chinese exports meet:

- ISO 9001:2015 certification

- CE machinery directives

- 36-month critical component warranty

Why Partner with China CZ Section Purlin Machine Suppliers?

Chinese manufacturers provide 67% cost advantage over Western counterparts while maintaining ≤0.2mm/m linear tolerance. With 140+ verified suppliers offering 24/7 technical support, production lines achieve ROI within 14-18 months. The combination of competitive pricing ($82,000-$220,000 per unit), rapid prototyping (7-10 working days), and containerized shipping solutions positions China as the primary source for purlin manufacturing systems.

(china cz section purlin machine)

FAQS on china cz section purlin machine

Q: What is a China CZ section purlin machine used for?

A: A China CZ section purlin machine manufactures CZ-shaped steel purlins, commonly used in roofing and structural frameworks. It ensures high precision and durability for industrial and construction projects. These machines are popular for their efficiency and cost-effectiveness.

Q: How to choose a reliable CZ section purlin machine supplier in China?

A: Look for suppliers with certifications like CE/ISO, proven industry experience, and positive customer reviews. Ensure they offer after-sales support and customization options. Direct factory visits or video inspections can further verify quality.

Q: What distinguishes a CZ section machine from a C section purlin machine?

A: A CZ section machine produces purlins with a deeper, zigzag flange design for enhanced load-bearing capacity. A C section machine creates simpler C-shaped profiles. The choice depends on structural requirements and project specifications.

Q: Can China-based suppliers customize CZ section purlin machines?

A: Yes, most reputable suppliers in China provide customization for roll-forming speed, material thickness, and purlin dimensions. They tailor solutions to meet specific project needs. Confirm customization capabilities during initial inquiries.

Q: What are the advantages of buying a C section purlin machine from China?

A: Chinese manufacturers offer competitive pricing, advanced automation, and adherence to international standards. Many provide global shipping and technical support. The machines are known for reliability and low maintenance costs.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025