cheap sheet metal roll forming machines

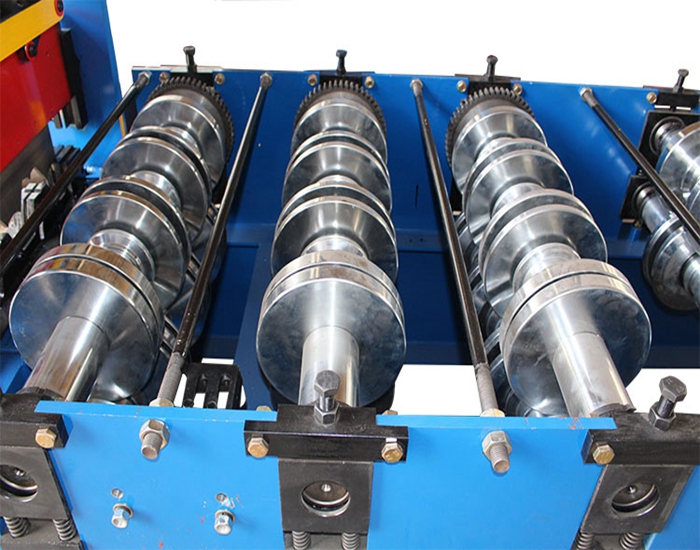

Understanding Cheap Sheet Metal Roll Forming Machines

In today’s fast-paced industrial world, efficiency and cost-effectiveness are paramount. For manufacturers working with sheet metal, one of the most effective processes is roll forming. This method, particularly when utilizing inexpensive machinery, can significantly enhance productivity while maintaining high-quality output. In this article, we will explore the concept of cheap sheet metal roll forming machines, their benefits, and considerations for choosing the right equipment.

What is Roll Forming?

Roll forming is a continuous bending operation in which a long strip of metal is passed through consecutive sets of rolls to obtain the desired cross-section. This process is widely used to manufacture various products, including metal roofing, siding, frames, and other components found in the construction, automotive, and appliance industries.

The Advantages of Roll Forming

1. Cost-Effectiveness The primary draw of cheap sheet metal roll forming machines is their affordability. Lower initial investment can make advanced manufacturing technologies accessible to small and medium-sized enterprises (SMEs), fostering innovation and competition.

2. Efficiency Roll forming machines can operate continuously, producing long lengths of material without the need for frequent setup changes. This continuous operation leads to high throughput, making the process highly efficient.

3. Material Savings Unlike other forming methods, roll forming reduces material waste. The process is designed to work with specific material dimensions, and any scrap generated can often be recycled, further reducing costs.

4. Precision Modern roll forming machines, even those that are cost-effective, offer excellent precision and repeatability. With the ability to create intricate designs consistently, manufacturers can meet rigorous specifications without sacrificing quality.

5. Versatility Cheap sheet metal roll forming machines can accommodate a variety of materials and thicknesses, making them suitable for different applications. Whether it's aluminum, steel, or other alloys, these machines can adapt to diverse manufacturing needs.

cheap sheet metal roll forming machines

Considerations When Choosing Cheap Sheet Metal Roll Forming Machines

While cost is a significant factor when selecting roll forming machinery, several other considerations should also be taken into account

1. Quality and Durability Ideal machinery should maintain performance over time, even at a lower price point. Researching the manufacturer’s reputation and reviews can help ensure you choose a reliable machine.

2. Specifications and Capabilities Understand your production requirements. Look at the machine’s specifications, including maximum width, thickness, and material types it can process. Choosing a machine that meets your specific needs is crucial for efficiency.

3. Customization Options Some manufacturers offer customization options for their roll forming machines. This flexibility can be beneficial as your production needs evolve over time.

4. Support and Service Consider the availability of technical support, spare parts, and maintenance services. A machine might be inexpensive upfront, but costly repairs or lack of support can negate those savings.

5. Installation and Training Factor in the costs and time associated with installation and staff training required to effectively run the machines. Opt for suppliers that offer comprehensive training and support to ease the transition.

Conclusion

Cheap sheet metal roll forming machines represent an excellent opportunity for businesses looking to enhance their manufacturing processes without breaking the bank. With numerous advantages like cost savings, efficiency, precision, and versatility, these machines can cater to a wide range of industrial applications. However, it’s essential to balance cost with quality, capability, and support to ensure a worthwhile investment. As you explore your options, take the time to research and choose machinery that aligns with your production goals, setting your business up for success in an increasingly competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025