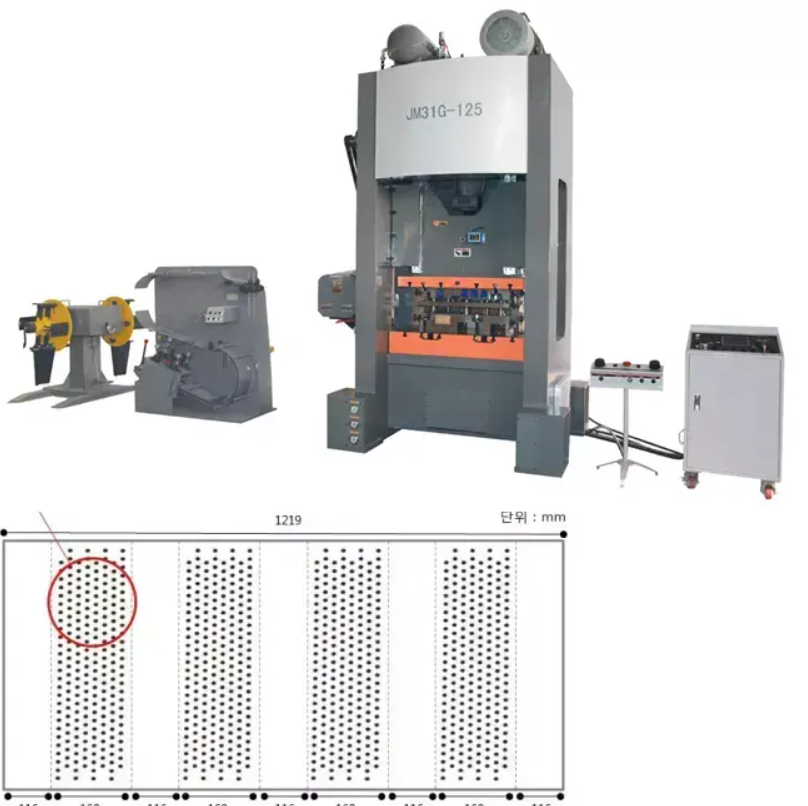

C-Channel Production Equipment Supplier for Efficient Manufacturing Solutions

The Rise of C Channel Making Machine Manufacturers A Comprehensive Overview

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency continues to grow. Among the myriad of machinery that has emerged to meet this demand, the C channel making machine stands out as a pivotal tool in various industries. These machines are designed to produce C-shaped steel channels, which are essential components in construction, automotive, and numerous engineering applications. As the demand for these profiles increases, so does the significance of reliable and innovative manufacturers of C channel making machines.

The Importance of C Channel Making Machines

C channels are widely used due to their structural integrity and versatility. They provide excellent support for structures, making them indispensable in framing, supports, and various load-bearing applications. The manufacturing process of these channels involves precision cutting, bending, and forming, which underscores the need for specialized machinery. C channel making machines automate these processes, enhancing productivity, minimizing waste, and ensuring uniform quality across batches.

Key Features of C Channel Making Machines

Modern C channel making machines are equipped with advanced technology that allows for precise control over the manufacturing process. Some key features include

1. High-Speed Operation Today's machines are designed for efficiency, capable of producing a significant number of channels in a short period.

2. Automation With automation, manufacturers can reduce labor costs and human error, leading to a more consistent product.

3. Customization Many machines can be tailored to produce channels of varying sizes and thicknesses, providing manufacturers with the flexibility to cater to specific market demands.

4. User-Friendly Interfaces Advanced C channel making machines come with intuitive interfaces that simplify operation and monitoring, making it easier for operators to manage the production process.

The Competitive Landscape of Manufacturers

c channel making machine manufacturer

As the industry grows, so does the competition among C channel making machine manufacturers. Companies must continually innovate and improve their equipment to maintain a competitive edge. Many manufacturers are now incorporating Industry 4.0 technologies, such as IoT (Internet of Things) connectivity, which allows for remote monitoring and predictive maintenance of machines. This integration not only enhances efficiency but also minimizes downtime, contributing to higher overall productivity.

Global Trends and Market Demand

The demand for C channel making machines is intricately linked to global construction and manufacturing trends. With urbanization continuing at an unprecedented pace, particularly in developing countries, the need for building materials has surged. Additionally, as industries strive to adopt eco-friendly practices, there is an increasing focus on using lightweight and durable materials, where C channels play a crucial role.

Furthermore, with the rise of automation and mechanization across various sectors, manufacturers are increasingly investing in high-quality machinery to remain competitive. This investment reflects a broader trend towards enhancing operational efficiency, sustainability, and product quality.

Choosing the Right Manufacturer

For businesses considering investing in C channel making machines, selecting the right manufacturer is critical. Key factors to consider include

- Reputation and Experience Established manufacturers with a proven track record often provide more reliable equipment and better after-sales support.

- Customer Service Excellent support during installation, training, and maintenance is vital for minimizing downtime and ensuring smooth operations.

- Customization Options The ability to tailor machines to specific needs can significantly impact production efficiency.

- Technological Advancements Manufacturers that continually update their technology can offer machines that improve productivity and reduce costs.

Conclusion

The landscape of C channel making machine manufacturers is rapidly evolving, driven by the need for efficiency, precision, and adaptability in manufacturing processes. As industries continue to innovate and expand, the importance of high-quality machinery will only increase. By staying abreast of technological advancements and market demands, manufacturers can not only meet but exceed the expectations of their clients, securing their place in an increasingly competitive marketplace.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025