roof manufacturing machine factories

The Evolution of Roof Manufacturing Machines A Look into the Future

In today’s construction landscape, roof manufacturing machines play a crucial role in ensuring efficiency and precision in the production of roofing materials. As the construction industry continues to grow, the demand for sophisticated machinery that can meet the specific needs of roof manufacturing factories has become increasingly evident. This article delves into the significance of roof manufacturing machines, the technology behind them, and how they are transforming the industry.

Understanding Roof Manufacturing Machines

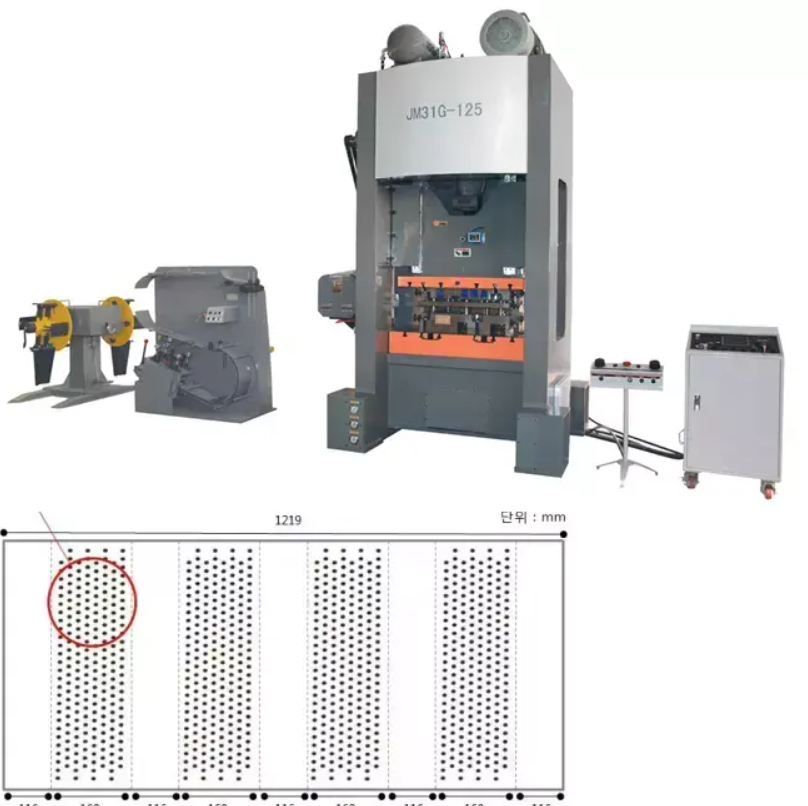

Roof manufacturing machines are specialized equipment designed to produce various roofing materials, including metal sheets, shingles, tiles, and membranes. These machines automate the manufacturing process, thereby increasing productivity while minimizing human error. They are engineered to handle a wide variety of raw materials and can produce roofing components that meet specific industry standards.

The manufacturing process typically begins with the feeding of raw material, such as metal coils or synthetic materials, which are then shaped, cut, and finished by the machine. Advanced technologies like Computer Numerical Control (CNC) enhance the precision of cuts and formations, ensuring that every product meets the required specifications. The integration of these technologies has revolutionized roof manufacturing, allowing factories to operate at unprecedented speeds while maintaining high-quality output.

Innovation and Technology

The evolution of roof manufacturing machines is closely tied to technological advancements. Modern roof manufacturing equipment incorporates innovative features such as automation, digital monitoring, and energy efficiency. Automation reduces the reliance on manual labor, leading to lower costs and higher production rates. Additionally, many machines are now equipped with sensors that monitor performance in real time, alerting operators to any issues that may arise during production.

Energy-efficient designs are also becoming more prominent in the industry. Manufacturers are increasingly focused on designing machines that consume less energy without compromising performance. This shift is not only beneficial for the environment but also leads to substantial cost savings for roof manufacturing factories.

The Role of Industry 4

.0roof manufacturing machine factories

The rise of Industry 4.0 has further propelled the development of roof manufacturing machines. The concept entails the integration of digital technologies into manufacturing processes, allowing for smarter, more connected operations. Roof manufacturers are beginning to adopt smart technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics.

IoT-enabled machines can communicate with each other, providing real-time data on production status, inventory levels, and equipment health. This connectivity allows manufacturers to streamline operations, reduce downtime, and enhance overall efficiency. AI can analyze vast amounts of data to predict maintenance needs and optimize production schedules, thereby maximizing output and reducing costs.

Challenges and Considerations

Despite the numerous benefits, the transition to advanced roof manufacturing machines is not without its challenges. One major concern is the initial investment cost, which can be substantial. Many factories may find it difficult to justify the expense of new machinery, particularly if they have older equipment that still functions adequately.

Moreover, the rapid pace of technological change means that manufacturers must continuously update their equipment and training. Keeping pace with innovations requires a commitment to ongoing education for employees and a willingness to adapt to new processes, which can be daunting for some businesses.

Looking Ahead

The future of roof manufacturing machines appears promising. As construction demands evolve and sustainability becomes ever more important, the industry will continue to seek out more efficient and eco-friendly solutions. The increasing use of renewable materials and the development of machines that can work with these new materials will likely be at the forefront of future advancements.

In conclusion, roof manufacturing machines are vital to the construction industry's efficiency and quality. Through continuous innovation and the adoption of advanced technologies, these machines will not only enhance production processes but also help meet the growing demands of a changing world. As factories invest in modern technologies, the potential for growth and improvement in the roofing industry is immense, paving the way for a sustainable and efficient future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025