metal roof sheet bending machine manufacturer

The Evolution of Metal Roof Sheet Bending Machines A Key Player in Efficient Roofing Solutions

In the modern construction industry, metal roofing continues to gain popularity due to its durability, aesthetic appeal, and energy efficiency. As a consequence, the demand for high-quality metal roofing materials has surged, leading to innovations in manufacturing processes. A crucial tool in this arena is the metal roof sheet bending machine. This article explores the significance of these machines, their functionalities, the role of manufacturers, and the trends shaping their future.

Understanding Metal Roof Sheet Bending Machines

Metal roof sheet bending machines are specialized equipment designed to shape and form metal sheets into the desired profiles for roofing applications. These machines utilize precise bending techniques to create various angles and curves, ensuring that metal sheets fit perfectly as roofing elements. The versatility of bending machines allows manufacturers to produce a wide range of roofing designs, from simple architectural profiles to complex shapes that meet aesthetic and functional requirements.

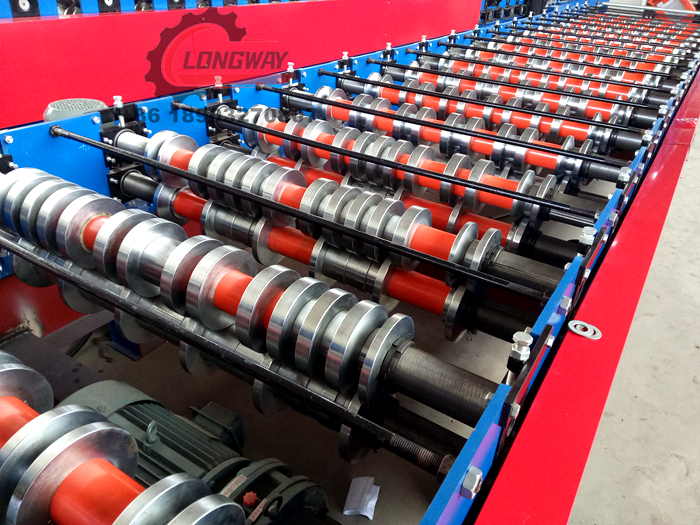

The primary components of a metal roof sheet bending machine usually include a hydraulic system, bending rolls, and control systems. The hydraulic system facilitates the bending process by applying significant pressure to the metal sheets, while the bending rolls shape the material into the required form. Advanced control systems enable operators to precisely monitor and manage the bending process, ensuring consistent quality and reducing material waste.

The Role of Manufacturers

Manufacturers of metal roof sheet bending machines play a vital role in the roofing industry. They are responsible for designing, producing, and supplying these machines to roofing companies and construction firms. A reputable manufacturer focuses on quality, innovation, and customer service, ensuring that their machines meet industry standards and customer expectations.

Selecting the right manufacturer is crucial for businesses looking to invest in a metal roof sheet bending machine. A reliable manufacturer will provide comprehensive support, including training for machine operators, maintenance services, and warranties. Moreover, they often stay updated with technological advancements and incorporate them into their products, ensuring that clients have access to the most efficient and effective bending solutions.

metal roof sheet bending machine manufacturer

Trends Shaping the Future

As the construction industry evolves, so do the technologies associated with metal roof sheet bending machines. Several trends are currently shaping their future

1. Automation and Smart Technology Many manufacturers are integrating automated systems and smart technology into their machines. This allows for more efficient production processes, improved accuracy, and reduced labor costs. For instance, automated bending machines can adjust parameters in real-time, ensuring optimal results with minimal human intervention.

2. Sustainability With an increasing focus on sustainability, manufacturers are developing machines that reduce material waste and energy consumption. Innovations in materials and machine designs help reduce the carbon footprint associated with metal roofing production.

3. Customization As the demand for personalized roofing solutions grows, manufacturers are offering customizable bending machines. This allows businesses to produce specific designs that cater to unique customer needs, enhancing their competitive edge in the market.

4. Enhanced Safety Features Safety is paramount in manufacturing environments. Manufacturers are incorporating advanced safety features in metal roof sheet bending machines, ensuring the protection of operators while maintaining high production rates.

Conclusion

Metal roof sheet bending machines are essential tools in the construction and roofing industries. As manufacturers continue to innovate and improve these machines, the entire sector can expect enhanced efficiency, quality, and design versatility. Investing in high-quality bending machines not only streamlines production processes but also contributes to the growing demand for aesthetically pleasing and sustainable roofing solutions. For businesses involved in metal roofing, partnering with a reputable machine manufacturer is a crucial step towards success in a competitive market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025