Advanced Metal Roll Forming Solutions from Leading Manufacturing Facilities Worldwide

Metal Roll Forming Systems Revolutionizing the Manufacturing Industry

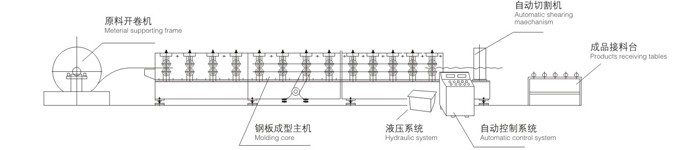

The manufacturing industry has seen tremendous advancements in recent years, and one of the most impressive developments is the emergence of metal roll forming systems. These systems have revolutionized the way metal components are produced, allowing for higher efficiency, precision, and versatility. This article will explore the significance of metal roll forming systems and the benefits they bring to factories around the world.

Metal Roll Forming Systems Revolutionizing the Manufacturing Industry

One of the primary advantages of metal roll forming systems is their efficiency. Unlike traditional manufacturing methods that may require multiple processes and significant manual labor, roll forming offers a streamlined approach. Once the tooling is set, the system can operate at high speeds, producing consistent and precise products with minimal waste. As a result, factories can significantly increase their production rates, meeting customer demands while also optimizing resource usage.

metal roll forming systems factory

Another critical benefit of metal roll forming is the high level of precision it provides. The rollers in roll forming systems are designed with precise tolerances, ensuring that the final product meets strict specifications. This precision is crucial in industries such as automotive manufacturing, where minor deviations can lead to significant issues in assembly and performance. By delivering consistently high-quality components, roll forming systems help manufacturers maintain reputation and reduce the costs associated with rework and scrap.

Furthermore, modern metal roll forming systems are equipped with advanced technology, including computer numerical control (CNC) systems. These innovations allow for real-time monitoring and adjustments during the production process, enhancing accuracy and efficiency. Additionally, manufacturers can easily switch between different product designs with minimal downtime, making roll forming systems an ideal choice for companies that need flexibility in their operations.

Sustainability is another aspect where metal roll forming excels. The process generates less waste compared to traditional manufacturing methods, which often involve cutting large sheets of metal into smaller parts, leaving behind scrap. The roll forming technique not only minimizes waste but also allows for the use of recycled materials, contributing to environmental conservation efforts. Factories that adopt these systems can improve their sustainability credentials while also reducing operational costs.

In conclusion, metal roll forming systems are redefining manufacturing efficiency, precision, and sustainability in the metalworking industry. As factories continue to seek ways to enhance productivity and reduce waste, investing in advanced roll forming technology is not just advantageous but essential. The ability to produce high-quality, uniform components at increased speeds positions metal roll forming as a cornerstone of modern manufacturing, ensuring that businesses can thrive in an increasingly competitive landscape. As technology advances, we can expect even greater developments in the capabilities and applications of metal roll forming systems in the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025