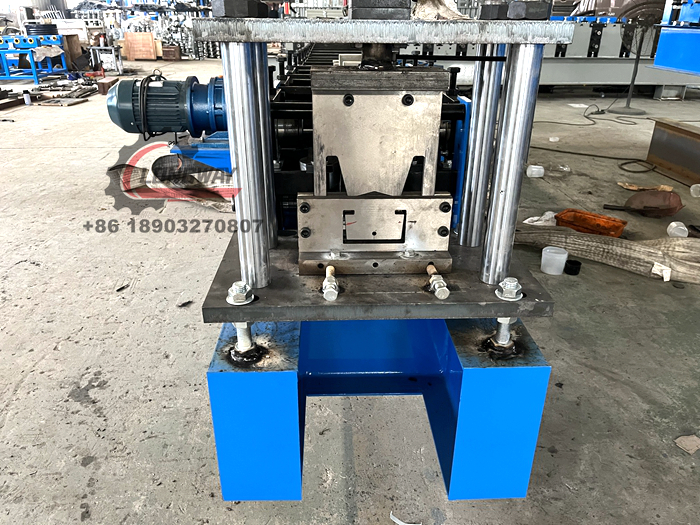

metal roof sheet forming machine

Metal Roof Sheet Forming Machine A Revolution in Construction

In the ever-evolving field of construction and building materials, the metal roof sheet forming machine stands out as a transformative innovation. This sophisticated equipment is designed to streamline the production of metal roofing sheets, ensuring efficiency, precision, and durability. As the demand for cost-effective and durable roofing solutions rises, understanding the functionality and benefits of metal roof sheet forming machines becomes increasingly important.

At its core, a metal roof sheet forming machine is engineered to convert raw metal coils into finished roofing sheets through a series of processes including shearing, bending, and rolling. The machine operates on a continuous basis, making it capable of producing large quantities of sheets in less time compared to traditional methods. This efficiency is a game changer for manufacturers who seek to meet the growing demands of the construction industry without compromising on quality.

One of the primary advantages of using a metal roof sheet forming machine is the customization it offers. Operators can easily adjust the machine settings to produce sheets of various sizes, thicknesses, and profiles, enabling them to cater to a wide range of architectural needs. Whether for residential, commercial, or industrial projects, these machines can create roofing materials that meet specific requirements, providing builders with the flexibility they need.

metal roof sheet forming machine

Durability is another key feature associated with metal roofing. Metal roofs are known for their longevity and resistance to the elements, including harsh weather conditions. The forming process enhances the structural integrity of the sheets, making them less prone to warping, cracking, or fading over time. Additionally, metal is inherently more fire-resistant compared to other roofing materials, offering peace of mind to homeowners and builders alike.

Moreover, the growing emphasis on sustainability in construction has made metal roofing a popular choice. Metal roofs are often made from recycled materials and are fully recyclable at the end of their life span, contributing to a reduction in landfill waste. Harnessing a metal roof sheet forming machine not only supports eco-friendly practices but also promotes energy efficiency. Metal roofs reflect solar heat, helping to reduce cooling costs in warm climates.

In conclusion, the metal roof sheet forming machine represents a significant advancement in the construction industry, marrying efficiency with customization and sustainability. As builders continue to seek out innovative ways to enhance project delivery and meet consumer expectations, this machinery is poised to play a pivotal role in shaping the future of roofing solutions. Embracing this technology could very well lead to a stronger, more resilient built environment.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025