iron roll forming machine

Iron Roll Forming Machine Revolutionizing Metal Fabrication

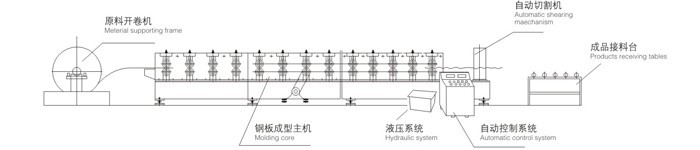

In the realm of metal fabrication, the iron roll forming machine has emerged as a pivotal player, providing industries with efficient and accurate solutions for shaping metal. These machines are specifically designed to create various metal profiles by passing a strip of metal through a series of rollers, each of which gradually bends the metal into the desired shape. The use of iron in this process adds to the durability and strength of the final products, making it a preferred choice for many manufacturers.

Understanding the Basics of Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, usually in coil form, is passed through consecutive pairs of shaped rollers. This method is highly effective for producing an array of cross-sectional profiles, including channel beams, angles, and z-sections. The process begins with feeding the metal strip into the roll forming machine, where it's guided through a series of rollers. Each roller adjusts the shape incrementally, and by the time the strip exits the machine, it is transformed into a finalized product ready for further processing or immediate use.

Advantages of Using Iron Roll Forming Machines

1. Precision and Consistency One of the most significant advantages of iron roll forming machines is their ability to produce precise and consistent profiles. Manufacturers can replicate designs with great accuracy, ensuring that each piece meets stringent quality standards.

2. Cost-Effective Compared to other metal shaping methods, roll forming is notably cost-effective. The efficiency of the process allows for high-volume production without the need for extensive labor, thereby reducing overall production costs.

3. Material Efficiency The roll forming process is optimally designed to reduce waste. The continuous operation of rolling strips minimizes scrap material, making it an environmentally friendly option.

4. Versatility Iron roll forming machines can create a variety of profiles, making them suitable for different applications. Whether it’s for the construction of roofing panels, automotive parts, or other structural components, these machines can adapt to diverse manufacturing needs.

iron roll forming machine

5. Integration with Other Processes Iron roll forming can be easily integrated with other production processes, such as punching, cutting, and welding. This capability further streamlines manufacturing operations and enhances productivity.

Applications of Iron Roll Forming Machines

Iron roll forming machines find applications across various industries. In the construction sector, they are used to produce roof trusses, wall panels, and framing components. The automotive industry utilizes these machines to create parts such as chassis and brackets. Additionally, the electrical industry relies on roll-formed products for manufacturing conduits and other supportive structures.

Innovation and Future Directions

As technology continues to advance, iron roll forming machines are also evolving. Modern machinery now incorporates automation and CNC (Computer Numerical Control) systems, allowing for even greater precision and flexibility in production. Additionally, manufacturers are exploring the use of materials that complement iron, potentially incorporating alloys that enhance specific characteristics like corrosion resistance or weight.

Moreover, as sustainability becomes increasingly vital in industrial operations, there is a growing emphasis on energy-efficient machines and processes that minimize environmental impact. Companies are investing in technologies that optimize energy consumption, further solidifying the role of iron roll forming in a sustainable future.

Conclusion

The iron roll forming machine is a cornerstone of modern metal fabrication, transforming how industries produce metal profiles. Its advantages in precision, cost-effectiveness, and versatility make it an essential tool in various applications. As the industry moves toward more innovative and sustainable practices, the future of iron roll forming looks promising, continuing to meet the demands of an evolving marketplace. Whether it’s in construction, automotive, or electrical markets, the roll forming process remains a vital component of efficient manufacturing.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025