double layer roof sheet roll forming machine manufacturers and suppliers information

Double Layer Roofing Sheet Roll Forming Machine A Comprehensive Guide

In the construction industry, the demand for efficient and versatile materials is ever-increasing. Among various choices, roofing materials hold paramount importance. The advent of double layer roofing sheets has revolutionized the building landscape, offering strength, insulation, and aesthetic appeal. The manufacturing process of these sheets is facilitated by advanced technology, particularly through double layer roofing sheet roll forming machines.

Understanding Double Layer Roofing Sheets

Double layer roofing sheets, as the name suggests, are manufactured in two layers, providing enhanced durability and insulation properties. They are commonly made from galvanized steel, aluminum, or other metal materials. The primary advantage of these sheets is their ability to offer two distinct styles or colors in a single product, catering to diverse architectural requirements and personal preferences. This functionality minimizes manufacturing costs and inventory needs for contractors and builders.

Introduction to Roll Forming Machines

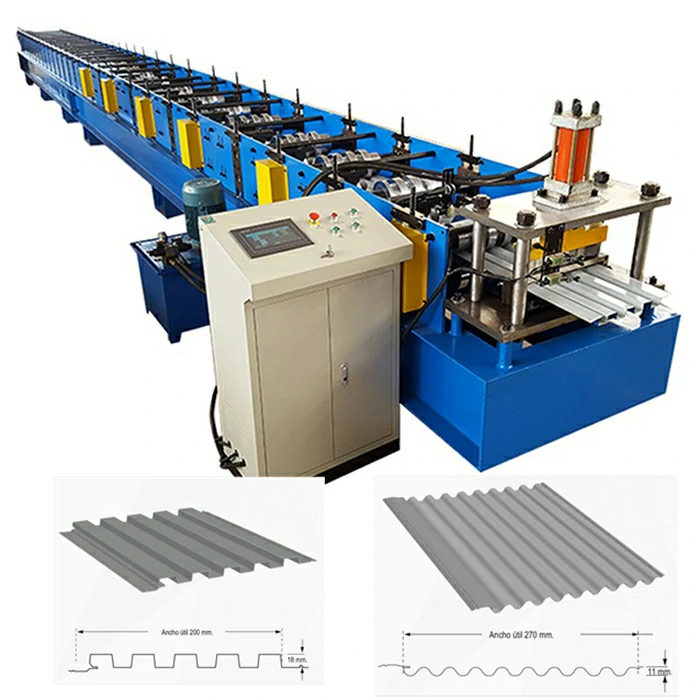

Roll forming is a process of shaping metal into specific configurations using a series of rollers. The design and engineering of roll forming machines have undergone significant evolution in recent years, leading to the development of specialized machinery for producing double layer roofing sheets. The double layer roofing sheet roll forming machine is equipped with dual roller systems, allowing it to produce different types of sheets simultaneously. This not only speeds up production but also ensures precision and consistency in the final products.

Key Features of Double Layer Roofing Sheet Roll Forming Machines

1. Versatility These machines can produce various profiles and designs of roofing sheets, accommodating the differing aesthetic demands of clients. Whether it’s a traditional look or a modern finish, the versatility of machine design can meet varied market needs.

2. Efficiency Double layer machines significantly increase production efficiency. By forming two layers at once, manufacturers can save valuable time and labor costs while also minimizing material waste.

3. High Precision These machines are designed with advanced technology to ensure precise measurements and cuttings. This is crucial for maintaining the structural integrity of the roofing sheets and achieving a flawless finish.

4. Durability and Reliability Built with high-quality materials, double layer roofing sheet roll forming machines are designed for long-term use in challenging factory conditions. Their reliable performance ensures consistent product quality.

double layer roofing sheet roll forming machine factories

5. User-friendly Operation Many modern machines include user-friendly interfaces and automated features, making it easier for operators to conduct setups, change designs, and maintain production lines.

The Manufacturing Process

The production process of double layer roofing sheets involves several steps

1. Raw Material Preparation The process starts with the selection and preparation of raw materials, often galvanized steel or aluminum, which are then fed into the roll forming machine.

2. Roll Forming The raw material passes through a series of rollers that shape it into the desired profile. In a double layer machine, the dual layer production takes place seamlessly, with the rollers configured to create both layers through precise adjustments.

3. Cutting After the roll forming process, the formed sheets are cut to the predetermined lengths automatically. This step is crucial for ensuring that the sheets fit perfectly when installed.

4. Finishing After cutting, the sheets may undergo additional finishing processes, such as coating or painting, enhancing their aesthetic appeal and corrosion resistance.

5. Quality Control Rigorous quality checks ensure that the final products meet industry standards and client specifications.

Conclusion

The rise of double layer roofing sheets has undoubtedly transformed the construction industry, providing builders with a versatile, efficient, and visually appealing option for roofing solutions. Through the use of advanced double layer roofing sheet roll forming machines, manufacturers are able to meet market demands effectively. As technology continues to evolve, we can expect even more innovations in the design and functionality of these machines, further enhancing their impact on construction practices around the globe. Investing in such state-of-the-art machinery is not just a step toward modernization; it is a commitment to sustainability, efficiency, and quality in the building sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025