custom roof sheet machine price

Understanding the Cost of Custom Roof Sheet Machines

In the construction industry, the demand for high-quality roofing materials has surged, leading to a parallel growth in the machinery used to produce these materials. Among these machines, custom roof sheet machines have become increasingly popular due to their capability to manufacture roofing sheets tailored to specific requirements. However, one of the primary considerations for businesses seeking to invest in such machinery is the price. This article will delve into the factors affecting the price of custom roof sheet machines and provide insights into what potential buyers should consider when making a purchase.

The Basics of Custom Roof Sheet Machines

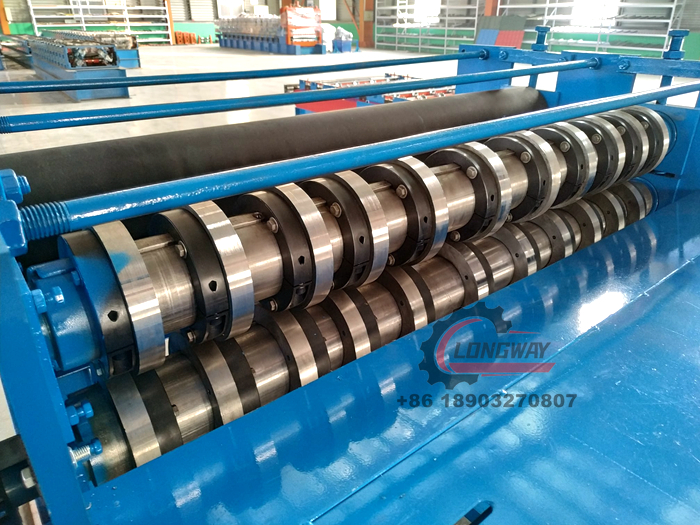

Custom roof sheet machines are designed to produce roofing sheets of various profiles, sizes, and materials. These machines are essential for manufacturers who need to meet specific design requirements or adhere to certain building standards. The functionality of these machines can vary significantly, depending on their design, production capacity, and technological features.

Factors Influencing the Price

1. Machine Specifications The price of a custom roof sheet machine largely depends on its specifications. Machines with higher production capacities, advanced features like automatic control systems, and the ability to produce multiple sheet profiles will typically come at a higher price point. Buyers should assess their production needs carefully to avoid overspending on features they may not utilize.

2. Material Used The type of materials the machine can process also affects the price. Machines designed for high-strength materials or those that require specific contours may necessitate more robust and sophisticated engineering, which can drive up costs.

3. Brand and Manufacturer The reputation and reliability of the manufacturer play a crucial role in pricing. Established brands known for their quality and customer service may charge a premium compared to lesser-known manufacturers. Buyers should consider the value of after-sales support, warranty, and technical assistance when evaluating the overall cost.

custom roof sheet machine price

4. Technology and Automation The level of technology integrated into the machine is another pivotal factor. Machines with advanced automation features can enhance efficiency and reduce labor costs, but they typically demand a significantly higher initial investment. Understanding the long-term benefits of automation versus the upfront cost is critical for potential buyers.

5. Customization Needs Since the machines are designed for custom production, any additional customization required—such as specific configurations, unique components, or tailored software—will impact the overall price. Buyers should have a clear understanding of their customization needs before engaging with manufacturers to get accurate pricing.

6. Market Trends The cost of raw materials and the overall demand for roofing products can influence machine prices. In periods of high demand or material shortages, prices may increase. Buyers should consider the market conditions and potential fluctuations when planning their purchase.

Making an Informed Purchase Decision

When considering the purchase of a custom roof sheet machine, it is vital to perform thorough due diligence. Engaging with multiple manufacturers to compare prices and specifications is a prudent approach. Additionally, seeking feedback from current users can provide valuable insights into the machine's performance and reliability.

It is also wise to assess the total cost of ownership, which includes maintenance, operation costs, and the potential return on investment. Understanding how the machine can streamline production processes and enhance product quality can ultimately justify the investment.

Conclusion

The price of custom roof sheet machines varies widely depending on specifications, manufacturing quality, technology, and customization. As businesses aim to meet growing demands for roofing materials, investing in the right machinery is crucial. By understanding the factors affecting price and being informed about their specific needs, buyers can make sound investment decisions that will enhance their production capabilities and contribute to their overall success in the competitive construction market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025