Customized Cold Roll Forming Machine | Precision Engineering Solutions

Customized Cold Roll Forming Machines Revolutionizing the Manufacturing Process

In today's fast-paced manufacturing environment, efficiency and precision are paramount

. One innovative solution that has emerged to meet these demands is the customized cold roll forming machine. These machines are designed to create a wide variety of metal profiles with high accuracy and less waste, making them indispensable tools in industries ranging from construction to automotive.Cold roll forming is a process where metal sheets are passed through a series of rollers at room temperature, allowing them to be shaped into a desired profile without the need for extensive machining. This technique not only enhances the structural integrity of the material but also improves its surface finish. The ability to customize these machines adds another layer of versatility, catering to specific production needs across different sectors.

One of the key advantages of customized cold roll forming machines is their ability to produce intricate and complex shapes. Manufacturers can design machines tailored to their specific requirements, ensuring that they can create components that fit perfectly into their project specifications. For example, in the construction industry, companies may require unique profiles for framing systems, while automotive manufacturers might need specialized parts for vehicle assembly.

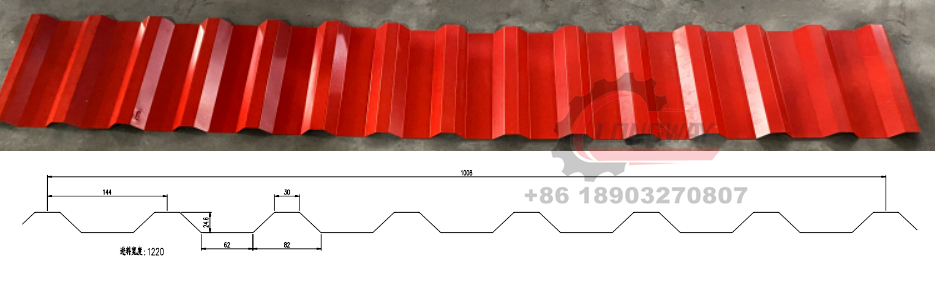

customized cold roll forming machine

Moreover, these machines are known for their high production efficiency. As they can operate continuously, they significantly reduce the time needed to produce large volumes of metal components. This capability is particularly beneficial for businesses that have high demand or require just-in-time production schedules. With reduced lead times, manufacturers can respond more swiftly to market changes, helping them maintain a competitive edge.

Additionally, the customization of cold roll forming machines contributes to reduced material waste. Traditional metal forming processes often generate scrap material, which can increase costs and impact the environment. Cold roll forming minimizes waste by allowing for precise metal usage, which is a crucial consideration in today’s environmentally-conscious market. By optimizing the use of materials, companies not only save on costs but also enhance their sustainability efforts.

In conclusion, customized cold roll forming machines are transforming the landscape of metal manufacturing. Their ability to offer tailored solutions, enhance production efficiency, and minimize waste makes them an invaluable asset across various industries. As technology continues to advance, the potential for even more sophisticated and efficient roll forming machines will undoubtedly shape the future of manufacturing, enabling companies to thrive in a competitive marketplace. Embracing these innovations will be key for businesses looking to elevate their operational capabilities and meet the evolving demands of their customers.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025